Navigating OSHA facility regulations

Conducting a physical assessment of a health care facility’s fall hazards is a critical first step in addressing fall protection.

Image from Getty Images

Whether a facility manager is new to the compliance field or a seasoned veteran, the words Occupational Safety and Health Administration (OSHA) can give them an uneasy feeling.

On top of the multitude of regulations needed for accreditation, adding OSHA to the list of responsibilities can often be the proverbial straw that breaks the camel’s back.

This article will provide some best practices to help health facility professionals comply with OSHA regulations while providing a safe and healthy work environment for hospital employees.

Weight of law

OSHA regulations carry the weight of law. The plain disregard of these requirements and the more innocent plea of “I just didn’t know” can have dire consequences. Not only can a facility suffer steep fines and penalties, but the issuance of civil and criminal penalties can be levied based on the severity and facts surrounding the violation.

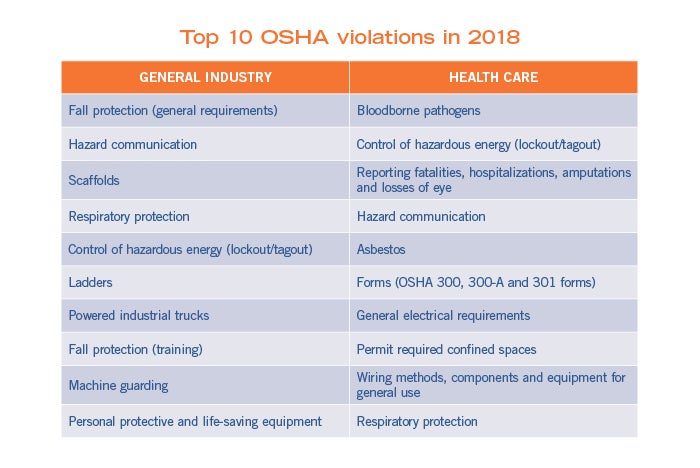

So what regulations are currently on OSHA’s radar? The top 10 violations from fiscal year 2018 across all industries and specific to health care are listed in a table below.

Like many government agencies, OSHA’s resources are often limited, resulting in personnel or funding shortages. Consequently, OSHA inspectors can’t be everywhere or inspect every facility. It’s important for facility managers to stay attentive to OSHA requirements for the safety of their coworkers and to take the necessary steps to minimize risks regardless of inspection history or the OSHA activity in their geographic area.

On the other hand, just because OSHA has a published regulation doesn’t automatically mean the particular risk exists for a given facility. It’s easy to over-allocate resources just because there are published standards instead of intently focusing on those standards that pose a significant risk to employees. It’s important to identify specific standards, quantify risk and focus on the areas of greatest weakness. The primary purpose is the protection of the most valuable assets of the organization — its employees.

Another point of interest, OSHA annually evaluates specific hazards or high-risk fields and focuses its inspection program on the fields having these hazards. This is known as the National Emphasis Program (NEP). Knowing which hazards are specific to the region of the country in which an organization resides may help facility professionals allocate resources and polish the programs that OSHA currently has on its radar. This NEP program of current and previous focuses and standards can be accessed at www.osha.gov/enforcement/directives/nep.

Most at risk

A review of a few of the citations from OSHA that put facilities and maintenance staff in health care most at risk include:

Fall protection. Fall hazards in a hospital environment can come in several forms. Conducting a physical assessment of a facility’s fall hazards is a critical first step in addressing fall protection. This assessment is followed by the quantification of risk for each fall hazard identified and then the implementation of proper protective measures.

When assessing an organization’s program, a few key considerations include:

- Does the facility have employees walking or working on horizontal/vertical surfaces with unprotected sides or edges?

- Is the facility utilizing guardrail systems, personal fall arrest systems, warning line systems or safety monitoring systems when a fall hazard exists?

- Does the facility utilize personal fall protection systems, covers or guardrail systems around skylights and other physical fall hazards?

- Does the facility have a comprehensive program that details how the organization is achieving and maintaining compliance?

- Do employees have training on personal fall arrest systems, such as safety harnesses, or when guardrails are needed?

OSHA has published a fact sheet pertaining to fall protection requirements.

The cascade of not starting out with a good fall protection program would be the subsequent top 10 citations that would follow, including “Fall protection (training)” and “Ladders.” The requirement for hands-on annual training would be part of this program. When reviewing the program using the questions above, facility professionals should ensure they address who, how often and what the training requirements will be for the fall hazards identified. To help, they can access an OSHA fact sheet at www.osha.gov/Publications/OSHA3903.pdf.

Hazard communication. The OSHA Hazard Communication Standard addresses chemical hazards in the workplace. This standard was first adopted in 1983 and has subsequently been revised several times. The most significant change in the regulation occurred in 2012 when the standard was revised to be consistent with regulations outlined in the United Nations Globally Harmonized System of Classification and Labeling of Chemicals. This standard has made OSHA’s top three for the past three years. In fact, OSHA issued 4,537 violations in fiscal year 2018.

When assessing an organization’s program, key considerations include:

- Does the facility have a written hazard communication program? Are employees being trained on the program?

- Is the training program comprehensive? Are employees trained on the hazardous chemicals prior to their work assignments and before the chemical is introduced to the workplace?

- Are employees trained on how to protect themselves from the hazards of the chemicals?

- Are Safety Data Sheets readily available for all hazardous chemicals in the workplace?

- When was the last time the program was revised?

- Does the program accurately depict what the health care organization is doing? Not only does this concept apply to the facility’s Hazard Communication Program, but to all of its health and safety programs.

OSHA has also published a guidance document that details the steps needed when developing a comprehensive Hazard Communication Program.

Scaffolding. The regulations applying to OSHA’s scaffolding standard can be found in the construction regulations under 1926.451. Because this standard applies more to construction activities and projects, it may not pose a significant compliance issue at a given health care facility but may impact many of the associate members working at the facility.

If a health care facility is planning to conduct construction-related projects such as a new building or addition, major renovations or elevated roof work, or if it has maintenance tasks that could involve scaffolding, this standard may apply. Even if a facility professional contracts this work to an outside firm, they must know what regulations apply to ensure the contractor is in compliance with the scaffolding standard.

Like many OSHA standards, there is usually a published list of applicable definitions or terms located near the front. It’s highly advisable that a facility manager become very familiar with these definitions to better understand the meaning of each term and determine whether the term applies to their organization.

A key term in the scaffolding standard is the identification of a “competent person.” The OSHA definition of competent person is “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.”

Another important term in the OSHA scaffolding standard is the term “qualified.” As it pertains to the scaffolding standard, it means “one who by possession of recognized degree, certificate or professional standing, or who by extensive knowledge, training and experience has successfully demonstrated his/her ability to solve or resolve problems related to the subject matter, the work or the project.”

A further look at the sections of the standard on which OSHA focused in 2018 includes:

- In section 451 (g)(1). All employees on a scaffold more than 10 feet above a lower level must be protected from falling. This section was most-commonly cited for violations in fiscal year 2018.

- In section 451 (b)(1). Each platform on all working levels of a scaffold shall be fully planked or decked between the front upright and the guardrail supports.

- In section 451(c)(2). Supported scaffold poles, legs, posts, frames and uprights shall bear on base plates and mud sills or other adequate firm foundation.

- In section 451 (e)(1). When scaffold platforms are more than two feet above or below a point of access, portable ladders, hook-on ladders, attachable ladders, stair towers (scaffold stairway/towers), stairway-type ladders (such as ladder stands), ramps, walkways, integral prefabricated scaffold access or indirect access from another scaffold, structure, personnel hoist or similar surface shall be used. Crossbraces shall not be used as a means of access.

OSHA has many resources available that highlight key aspects of the scaffolding standard.

Respiratory protection. In 2018, respiratory protection was another standard frequently cited by OSHA. This standard can be quite daunting and complex for facility managers. They may already know that most health care personnel, especially nurses and doctors, use respirators to prevent exposure to dangers such as tuberculosis and other inhalable aerosols. However, when it comes to respiratory protection, hospital facility and maintenance employees often can be overlooked.

These employees need to comply with this standard not only for compliance purposes but for protection. The protection of facility employees from respiratory hazards must be a top priority as these hazards are common, resulting from activities such as installing/removing insulation, handling harmful chemicals, working inside confined spaces, and the respiratory protection used during emergency management situations or drills.

Because this program can be complex, there is help and guidance available to facility managers. OSHA has published several resources to help those developing a comprehensive program or wanting to see how their program stacks up against the current standard. A beneficial resource used for this purpose can be found at www.osha.gov/Publications/OSHA3767.pdf.

This tool kit is focused toward health care personnel and covers why hospitals need respiratory protection programs, types of respirators and developing a respiratory protection program. At the end of the tool kit is a reference resource and tools section.

A few key questions facility managers should ask regarding compliance with OSHA’s respiratory protection standard include:

- Who is the facility’s suitably trained program administrator, as required by the standard?

- Does the facility have a comprehensive written respiratory protection program, and when was the program last revised or reviewed?

- Do employees know that a respiratory program exists, and do they know how to access it?

- Are employees provided training on the elements of the program and why and when respiratory protection is needed? If employees are required to wear a respirator, do they understand the type and limits of their respirators and how to properly wear, don/doff and store the respirator?

- If employees are required to wear a respirator, are they provided the proper medical clearances to safely wear a respirator without adding a further burden on them physically and medically?

Lockout/tagout (LOTO). The control of hazardous energy is a potential source of serious injuries and citations for an organization. These hazards are minimized by using LOTO procedures found in OSHA 1910.147. Hazardous energy includes electrical, pneumatic, hydraulic, fuel gases and gravity, among others. The employer is required to have a written LOTO program with specific lockout procedures for equipment. Equipment must be de-energized before employees may work on it.

The standard requires employers to train employees. There are different levels of training for authorized employees, affected employees and other employees. In essence, all employees at the facility will need some type of LOTO training. OSHA has a page dedicated to LOTO that has a lot of resources.

Employees who perform the work or the authorized employees must de-energize and physically place a lock or other device on the equipment being serviced. If there are multiple employees working on the same equipment, they must use group LOTO procedures, and each individual employee must have their lock on each lockout point.

In addition, only the authorized employee who placed the lock may have a key to remove the lock. This is to prevent miscommunication between employees and prevent the premature re-energization of equipment.

When assessing a facility’s LOTO program, questions that need to be asked include:

- Who are the employees performing maintenance and servicing of equipment, and are they exposed to hazardous energy?

- Have authorized, affected and other employees been trained in LOTO?

- Do the facility’s employees have the proper tools to perform LOTO, such as locks, tags and other devices?

- Has the facility developed machine-specific LOTO procedures, and do employees follow them?

- What are employees’ attitudes toward LOTO? Do they understand group LOTO procedures? Do they know equipment can have more than one source?

The road to compliance

The pressures of running a health care facility are immense, and adding OSHA compliance to the mix can at times seem overwhelming.

Facility professionals should risk-assess the current OSHA standards and determine their vulnerabilities. After gathering data from sources like accident data, risk management reports and previous inspection findings, facility professionals should quantify it and rank it based on likelihood, consequence and severity. The quantification of risk pertaining to OSHA programs will tell the facility professional which program needs to be addressed first.

Additionally, they may want to consult with the facility’s environment of care committee or on-site safety personnel to get their input.

It may also be beneficial to reach outside the organization to additional sources of information such as OSHA’s consultative services, experts in the field or courses on the topic. These resources may also come from peers who are in the same boat and may have already successfully addressed the areas a facility is struggling with.

Another great resource available to facility managers and ASHE members is the ASHE online community, “My ASHE,” at https://my.ashe.org. At this site, compliance questions are asked and discussions held on numerous current issues impacting facility managers.

The road to OSHA compliance is not an easy one. However, at the end of the day, health facility professionals need to remind themselves that above all the pressures and conflicting priorities, the safety and health of the facility’s employees must remain paramount.

Joseph Losko, D.Sc., CSP, CHMM, is assistant professor, safety management department, Slippery Rock (Penn.) University; Danielle Gathje, CHFM, is regional director, facility operations, Fairview Health System, Minneapolis; and Angela Bernardo, Ph.D., CSP, is associate professor, safety management department, Slippery Rock University. They can be reached at joseph.losko@sru.edu, dgathje1@fairview.org and angela.bernardo@sru.edu.