Seismic test building is ready to rock

Any day now an earthquake will hit Southern California — more precisely, a very tiny piece of Southern California. But no one is fretting about this temblor.

Any day now an earthquake will hit Southern California — more precisely, a very tiny piece of Southern California. But no one is fretting about this temblor.

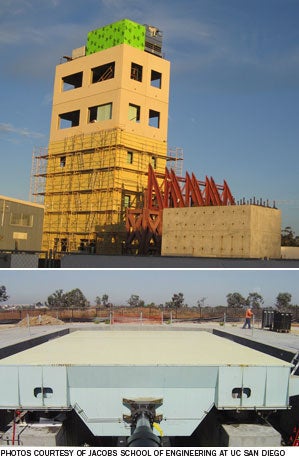

That's because the quake will be simulated using the largest outdoor shake table in the world to move a five-story concrete building that includes two floors designed and equipped to duplicate hospital clinical spaces.

Structural engineers from the University of California San Diego (UCSD) will conduct earthquake simulation tests beginning next month to measure the impact on nonstructural components and building systems. The goal is to determine if design changes are needed to minimize damage from earthquakes and related fire.

Intense ground motions generated by the steel-plated shake table, which is powered by hydraulic actuators underneath, can simulate quake levels as intense as those expected for the San Andreas fault in California.

The building and shake table are equipped with more than 500 sensors and 70 digital cameras to measure the impact of the motion on the mechanical, electrical, fire protection and other nonstructural components. Damage to nonstructural components has had a significant impact on the operation of hospitals after an earthquake.

For that reason, two of the five floors have been designed and built to closely duplicate health care facility clinical spaces, says Tara Hutchinson, P.E., professor in the department of structural engineering at the Jacobs School of Engineering, UCSD, and principal investigator on the project.

"From the interior point of view, the architectural features and the equipment features will be as realistic as we can attain," says Hutchinson.

"We should be able to observe interactions between several systems in the building for the first time," says Jose Restrepo, professor of structural engineering at the Jacobs School of Engineering and co-principal investigator on the hospital project with Hutchinson. "We will learn if current design requirements are satisfactory and recommend adjustments if necessary."

One floor is set up as a surgery suite equipped with medical devices and other equipment such as a patient lift and beds, wall-mounted equipment and mobile computers. The second hospital floor is designed as an intensive care unit equipped with nurse call stations, patient beds and medical equipment such as imaging machines, says Hutchinson.

The hospital floors will include interior fire-rated gypsum walls and a ceiling and subsystem that would be found in a typical hospital, she says. A medical gas line has been installed along with regular plumbing lines, a fire sprinkler system and HVAC ducts.

Hutchinson says plumbing systems are usually vulnerable during earthquakes, making them an important aspect of the testing. "Failure of these small piping systems, because they're attached at several locations, is common. The failure of even these small systems can render the hospital nonfunctional at the very time that its services are in high demand," she says.

Hospitals need to remain functional and operational after a major seismic event, which means they need special attention when it comes to design, installation and construction, Hutchinson says.

Since the 1970s, engineers have endeavored to determine how to improve building design codes after hospital system failures occurred in the wake of earthquakes, she says. While research has been conducted in the past, nothing to this level of detail has been done, Hutchinson adds.

The team also will conduct fire tests, says Restrepo. "These tests will allow us to observe the post-earthquake performance of the different fire barriers and see if such barriers are affected by the movement of the building during strong earthquakes," he says.