Maintenance software applications expand

Image courtesy of Fluke Corp.

The ideal computerized maintenance management system (CMMS) encompasses more than work order tracking and maintenance scheduling. It provides users with the insights needed to manage maintenance proactively, increase equipment reliability, ensure compliance with internal and external regulations, and support a sustainable environment.

In short, a properly utilized CMMS can transform maintenance activities into a business value driver. Many providers of CMMS software have achieved this goal by offering systems that embrace mobility, connectivity and visualization. The “internet of things” and artificial intelligence (AI) are driving further improvements in efficiency.

Many challenges

Hospitals pose many challenges to CMMS providers. For instance, health facilities are subject to an above average rate of change in floor plan configurations and relocation of care assets. Thus, implementation of CMMSs requires accurate information related to asset locations, preventive maintenance histories and the ability of staff to respond to emergencies.

Environmental and energy management pose challenges to CMMSs as well. Hospital equipment coupled with other environmental systems — heating, cooling and lighting — are major energy-consuming assets. Any effort to manage energy consumption requires the ability to track where energy is dissipated.

Cybersecurity is another challenge. Integrations of various third-party applications with CMMSs and a growing number of equipment connected to the hospital network have increased the risk of a breach. “This makes it important for the system to expertly manage integrated medical devices and ensure compatibility with various cybersecurity-focused applications,” says Ben Mannisto, president and CEO of Phoenix Data Systems, Southfield, Mich.

Another issue is dealing with the changing dynamic in the skill set of technicians responsible for maintaining the equipment within a hospital, according to Kyle Adamo, health care product manager at Dude Solutions, Cary, N.C. “There is now a generation gap, where the older generation is expert in trades and problem diagnosis, while the younger generation is expert in technology as a workflow and productivity tool,” Adamo says. “Bridging this gap is a huge challenge.”

Internet of things

The internet of things is a major component of the evolution of CMMS software, according to Michael Watson, product application specialist at Fluke Corp., Everett, Wash. “Most of today’s CMMSs are in a software-as-a-service model and, therefore, already in the [internet of things] realm. While the [internet of things] affects hospital CMMS software, it’s not a negative. Instead, the [internet of things] space is enhancing and enabling connected sources.”

Rick Joslin, senior adviser, health care strategy at Accruent, Austin, Texas, says the internet of things is enabling hospitals to automate and gather real-time, actionable information on equipment that traditionally required manual processes.

“Refrigeration temperatures can be sent to CMMSs and recorded in a historical format,” Joslin says. “Airflow rates can be logged against HVAC equipment and trended or manipulated in real time. Medical equipment preventive maintenance and inspection results can be uploaded and stored without additional steps.”

Joslin stresses that CMMS software must have the ability to incorporate these data values into actionable records, enabling health care staff to make critical decisions with near-instant results.

Adamo sees a monumental shift in the type of equipment that is connected to the internet. “Historically, CMMS providers only had to deal with desktop, laptop and, most recently, mobile device users, but now there’s a growing fire hose of data coming from building automation systems, temperature sensors and other connected equipment,” he says. “Most of this data takes the form of monitoring feeds, self-diagnostics and alerts that are driven to separate applications and interfaces.” It’s the job of CMMS providers to tap into this data so that users can centralize oversight of all equipment.

Taking the internet of things connection to the next level, Smart Facility Software, Nashville, Tenn., has developed web services for its environmental services-based CMMS that facilitate communication among machines, mobile devices and web-based databases to improve the flow of information among technicians, management and administration.

“ES Optimizer’s push in recent years has been ‘making managers mobile.’ We’ve built systems to get facility information to them wherever they are on the floor — and the means to manage their staff from mobile devices,” says Mark Clabaugh, chief information officer/chief technology officer at Smart Facility Software. “Now, we are working on the same thing with information from machines.”

This flow of information makes managers more effective on the floor. “We are working with machine manufacturers to improve communications with management so that when a condition exists that needs their attention, we can document and assign that task through our platform,” Clabaugh says.

Other innovations

Mobility, connectivity and visualization are key features of the latest CMMS solutions available to health care.

EQ2 LLC, Charlotte, N.C., which offers HEMS CMMS software, recently introduced a call escalation module and call assignment module. Call escalation automates the transfer of work orders to next-level technicians at a predetermined interval. With call escalation, department managers don’t have to monitor the workflow within their unit, and there is a dashboard to monitor the work.

EQ2 also has introduced HEMS Remote, its second mobility application available for Apple, Android and Windows products. It works without a network connection, which gives maintenance staff more flexibility. HEMS Remote provides a work order dashboard along with documented hours on the home screen, so technicians know where they stand at all times.

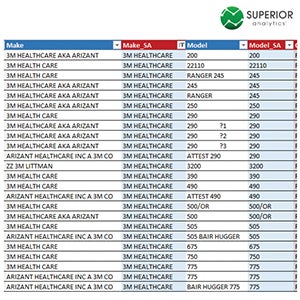

Phoenix Data Systems has added several metrics packages to its suite of data cleaning, normalization and analytics products designed to identify cost inefficiencies and labor effectiveness. “The first is alternative equipment maintenance (AEM) analysis, which provides a way to jump-start your AEM program by comparing a hospital’s devices with Phoenix’s database of participating hospitals, which allows users to identify devices that have been included in other AEM programs,” Mannisto says. “The second, equipment risk assessment, reveals data inconsistencies that are often overlooked.”

zLink Inc., Maynard, Mass., recently expanded its zLinkFM platform to include new software components that provide extensive inventory management capability out of the box, according to Anupam Sachdev, the company’s CEO. In addition, the company’s capital planning module allows for the integration of deficiency remediation-based projects and new or add-on construction efforts.

All CMMS functions in the zLink platform are available on mobile platforms. “The tight coupling of architectural drawings and functional data allows for the easy visualization of information,” Sachdev says. “The key features are real-time access to work requests using mobile apps, easy access to asset maintenance status data, and space-centric visualization by integrating floor plans and data on mobile devices.”

Dude Solutions Inc. now offers a space management add-on to its CMMS, TheWorxHub. It allows hospital staff to visualize all of their architectural and life safety drawings. “It adds a new dimension to equipment and work data when you can visualize them on a drawing and can easily locate files related to those spaces or equipment,” Adamo says. “For new staff, it’s a great tool to get acquainted with the physical structure.”

JLL, Chicago, offers CMMS Corrigo mobile and web-based apps that connect technicians, service providers and facility managers. Corrigo can help dispatch work to third-party vendors as well as invoicing. The module streamlines the billing process, which allows maintenance professionals to focus more on improvement of the care environment.

“Another feature being created for Corrigo is interim life safety measures (ILSM). When corrective work is being assigned, a flag is tied to the ILSM module,” says George Mills, director of health care technical operations. “If the work is being done in an area identified as a potential risk to patients, family members or staff, the technician can identify appropriate life safety measures.” In a similar fashion, if the work is specific to Life Safety Code compliance, the technician can select the ILSM module and appropriate actions. This creates a report that is tied to a compliance module for follow-up.

SMGlobal Inc., Apex, N.C., recently released FastMaint CMMS v.10, which allows users to schedule both preventive and corrective maintenance, and send orders via mobile phones. Upgrades include a statistics report on the main screen that shows total labor hours and spare part cost totals for specific periods. Via hyperlinks, users can access reports showing where most labor time was spent and which parts were used most often during a specific reporting period.

Intelligent future

CMMSs in health care will evolve to become a central source of record for all things in the environment of care, according to Joslin. He believes that medical equipment procurement, maintenance and disposition decisions will originate from CMMS data; utility system upgrades and design will begin with integration capabilities in mind; and automation in environmental management and patient experience will be the norm.

“But CMMSs must have the ability to grow into these advanced technologies,” Joslin says. “They cannot remain a repository of information; they must become the center of decision analytics. Mobile platforms are a good beginning, but CMMSs must consider voice navigation and execution as the next logical step.”

Clabaugh foresees better devices and more reliable connectivity. “Every week, we see hospitals focusing attention on wireless capabilities within their facilities. This is bringing a lot of opportunity with regard to communications and remote monitoring of situations. Devices, cameras and video technology are advancing at a rapid pace, which is improving the delivery of CMMS application services.”

Many companies also are pointing to AI as playing a key role in the development and use of CMMSs.

Watson says the immediate role of AI will play out in the form of “fault mode” detection and corrective action automation. This means that AI isn’t just coupled with edge computing devices but also with aggregated data, storage repositories and analysis programs.

“The days of prescriptive maintenance are well within reach,” Watson says. “This will give the health care field the platform needed to move from a largely risk-based maintenance approach to a condition-based philosophy.”

As devices and equipment connected with the internet of things proliferate, there will be a change in the amount of data flowing into CMMSs, according to Rich Sable, product manager at EQ2.

“By using AI, the software will become more predictive and work assignments more proactive,” Sable says. “This new data will be used by CMMSs to automatically order parts and notify technicians when to perform service.” He adds that CMMSs will be able to “learn” the maintenance patterns and create new schedules based on that data.

Neal Lorenzi is a freelance writer and regular contributor based in Mundelein, Ill.

UP AND RUNNING

By using a CMMS, hospital maintenance teams are able to better track asset health and current operating status, thus allowing them to improve asset uptime and life cycle. Fluke Corp.

ON THE GO

The HEMS Remote mobile app enables users to work offline to access work order details and sync the user’s updates once connected again. EQ2 LLC

GREAT INSIGHT

Connectiv provides an integrated view of a system via dashboards, reports and notifications to better understand processes and drive continual improvement. Accruent

COMPLETE VIEW

The Corrigo dashboard shows compliance progress in all areas managed by the facilities team. JLL

MINING DATA

Superior Analytics has uncovered extensive amounts of inconsistent medical device data. Phoenix Data Systems

QUICK COMMUNICATION

FastMaint CMMS v.10 allows users to schedule preventive and corrective maintenance, and send orders via mobile phones. SMGlobal Inc.

NOW AND THEN

Technicians receive both scheduled and on-the-fly tasks via a mobile device. Smart Facility Software

ALL MAPPED OUT

Space Management, an application within TheWorxHub, converts assets and tasks, such as preventive maintenance and environment of care workflows, to an interactive map format. Dude Solutions Inc.