Hospital's heating and power solution continues to prove its worth

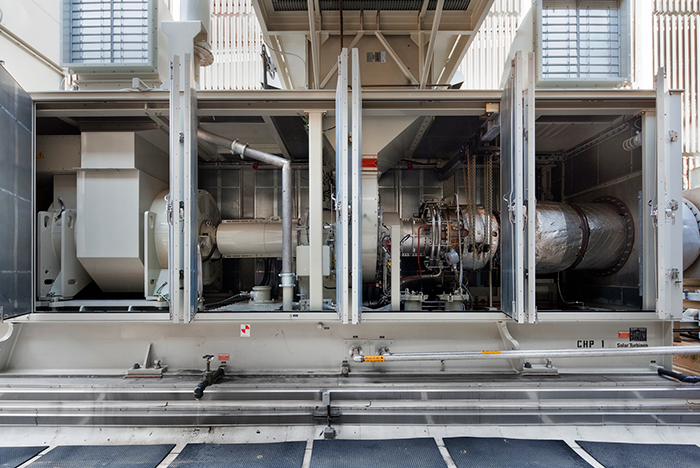

Houston Methodist Hospital invested in a cogeneration heating and power system in 2011 to serve its expanded facility.

Image courtesy of Houston Methodist Hospital

Health care organizations are continually innovating around sustainability and cost savings, and it’s easy to focus on the latest technology and engineering that drives those initiatives. In contrast, enduring achievements that may not be new or groundbreaking but continue to function with elevated levels of reliability and productivity can be taken for granted. Such is the cogeneration heating and power (CHP) system installed in 2011 at Houston Methodist Hospital in Texas.

Plans for the new system began in 2008, driven by expansions at the hospital campus which made it necessary to increase the existing central utility plant’s capacity. The existing infrastructure was also inefficient, environmentally unfriendly and expensive. Additional steam, cooling tower capacity and backup power were specific requirements, and the planners compared traditional boiler, diesel generator and cooling tower solutions to a CHP alternative. Although the CHP system came with higher overall initial costs, they were outweighed by the additional energy security and reliability the system would provide.

The cogeneration plant's upfront cost is overshadowed by the energy efficiency and cost savings the system has reaped over the past decade-plus.

Image courtesy of Houston Methodist Hospital

"Cogeneration, or combined heat and power, was a game changer for us," explains Isaiah Anzewu, a power plant engineer with Houston Methodist, and a key figure in the system's implementation. "It’s not just about saving money. It’s about reducing emissions and ensuring that critical services remain uninterrupted, even in the event of a grid failure."

The system includes a 4.6-MW natural gas-driven Centaur 50S gas turbine from Solar Turbine based in San Diego, Calif., a 2,800-ton steam drive centrifugal chiller, heat recovery steam generator with a supplementary duct burner and an aqueous ammonia selective catalytic reduction scrubber. It operates between 7,000 to 8,000 hours per year and can provide the five-building complex with almost half of the steam and more than 50% of the chilled water it demands.

The system captures and utilizes waste heat generated during electricity production, which would otherwise be lost in traditional setups. This proven process significantly increases energy efficiency, slashes fuel consumption and curbs emissions compared to generating power and heat separately.

Best of all, the system eliminated the organization’s reliance on an external power grid and separate heating systems, providing a more sustainable and reliable energy solution. However, the undertaking was not without its challenges. Anzewu recalls the initial hurdles of integrating the cogeneration system into existing infrastructure, managing costs and ensuring minimal disruption to hospital operations. However, through meticulous planning and collaboration with experienced engineers, these challenges were addressed and met.

"The key lesson we've learned is the importance of total planning and collaboration," Anzewu reflects. "Engaging stakeholders early, leveraging expert knowledge and adopting a proactive approach are crucial to the successful implementation of sustainable energy solutions."

And the payoff? Beyond the tangible cost savings of almost $2 million a year, the system’s impact reverberates throughout the hospital. The CHP system continues to improve the hospital’s energy security and reliability by eliminating the need for a diesel backup generator. With electricity produced on-site and waste heat utilized for heating and cooling, funds that would have been spent on energy bills are redirected toward patient care and other facility enhancements.