Maintenance practices for all-electric utilities

The University of California, Irvine, and UCI Health medical complex will be powered by clean energy generated by a state-of-the-art central utility plant running on solar and electric power.

Image courtesy of UCI Health

Central utility plants (CUPs) are essential in health care operations, providing critical utilities like electricity, heating, cooling and medical gases. Traditionally, these plants have relied on fossil fuels such as natural gas and oil for energy generation. However, the emergence of all-electric CUPs powered by renewable energy sources is challenging the status quo and paving the way for a more sustainable future.

With the growing focus on sustainability and the increasing adoption of renewable energy sources, there continues to be a noticeable shift in the way CUPs are designed and operated. These modern systems leverage renewable energy sources, advanced monitoring technologies and predictive analytics, significantly reducing reliance on fossil fuels and minimizing carbon emissions.

As the push toward sustainability intensifies, the shift from traditional to all-electric CUPs is becoming more pronounced. This article explores the dual focus of integrating all-electric CUPs in health care settings and the critical role of facilities managers in the design, construction and maintenance of these new systems.

Maintenance strategies

The evolution of health care infrastructure, particularly in the construction and operation of CUPs and hospital facilities, marks a significant pivot toward sustainability and operational efficiency. Maintenance strategies play a crucial role in ensuring the efficient and reliable operation of CUPs.

Traditional maintenance methods have typically focused on reactive and preventive approaches, while the maintenance of all-electric CUPs requires a more proactive and sustainable mindset. A discussion of the major characteristics and requirements of traditional and all-electric CUPs includes:

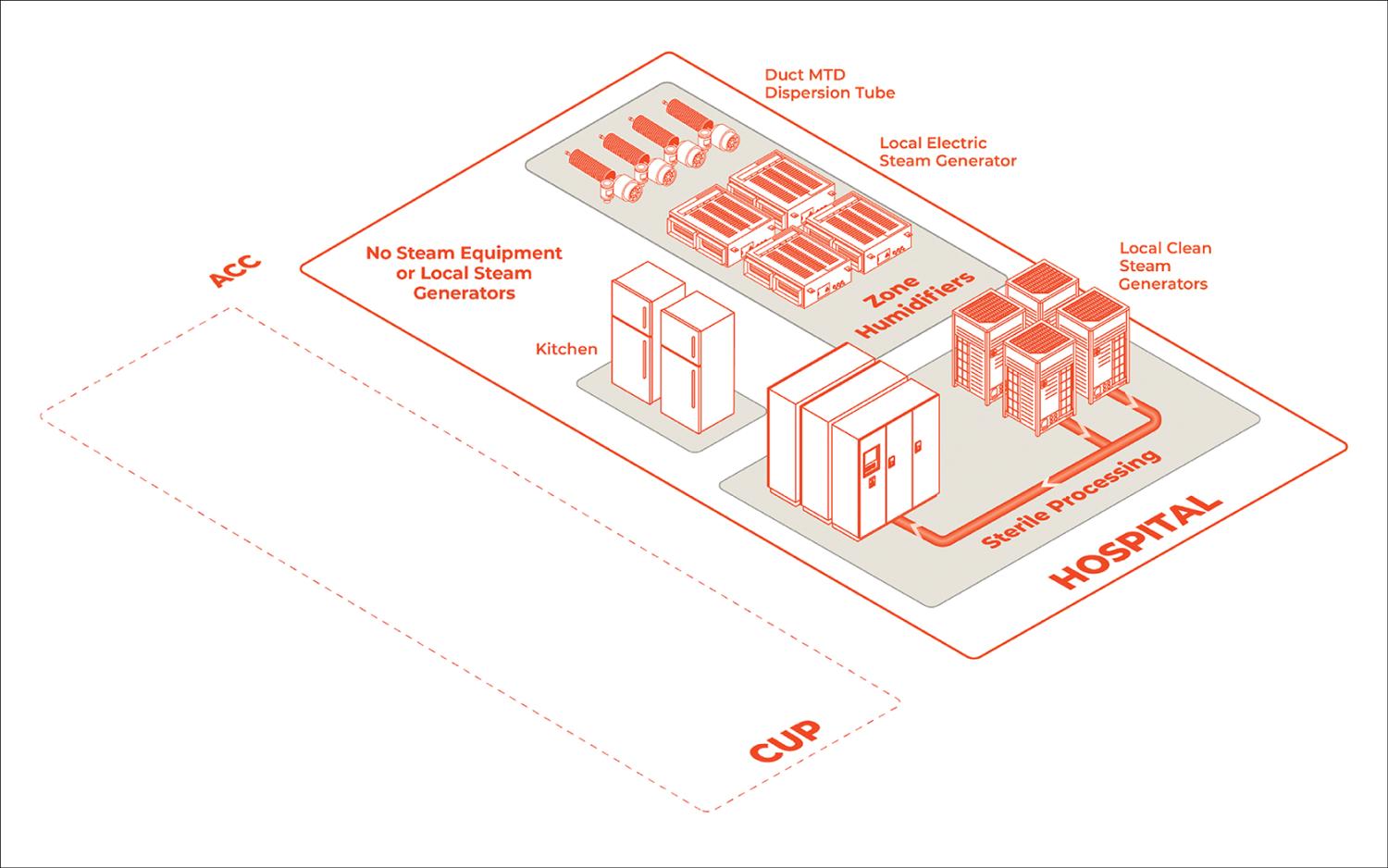

The all-electric central utility plant shown in relation to the hospital, parking facility and ambulatory care facility in the UCI Health complex currently under construction.

Image courtesy of UCI Health

Traditional CUPs. In traditional CUPs powered by fossil fuels, maintenance strategies have often been reactive in nature. Maintenance tasks are performed in response to equipment failures or performance issues, which can lead to costly downtime and potential safety hazards. Preventive maintenance is also commonly used to replace components or conduct inspections at predetermined intervals to prevent equipment failures. While these strategies have been effective in ensuring the reliability of CUPs, they may not be sustainable in the long run, given the environmental impact of fossil fuels and the changing regulatory landscape.

Cultural aspects play a significant role in shaping maintenance practices in CUPs. In many organizations, there is a prevailing mindset that prioritizes short-term cost savings over long-term sustainability. This mindset can lead to a reluctance to invest in new technologies or adopt more sustainable maintenance strategies. Additionally, the hierarchical structure of some organizations can create barriers to communication and collaboration among maintenance teams, hindering innovation and the adoption of best practices.

From a sustainability perspective, traditional maintenance practices in CUPs powered by fossil fuels pose significant challenges. The reliance on non-renewable energy sources contributes to greenhouse gas emissions, air pollution and resource depletion. Additionally, the disposal of hazardous waste from maintenance activities can have negative environmental impacts.

As the demand for clean energy solutions increases, there is a growing need to transition toward more sustainable maintenance practices in CUPs.

All-electric CUPs. All-electric CUPs represent a paradigm shift in the way energy is generated and distributed. These facilities rely on renewable energy sources such as solar, wind and hydroelectric power to meet their energy needs, resulting in reduced carbon emissions and environmental impact.

Maintenance strategies in all-electric CUPs focus on maximizing the efficiency and reliability of renewable energy systems while minimizing downtime and environmental impact. They emphasize a proactive approach to asset management and maintenance. Predictive maintenance techniques, such as condition monitoring and predictive analytics, are used to identify potential equipment failures before they occur.

By monitoring key performance indicators and using advanced data analysis tools, maintenance teams can detect early warning signs of equipment malfunction and take corrective action to prevent downtime. This proactive approach minimizes unplanned maintenance activities and maximizes the lifespan of critical assets. Some examples of the opportunities that the current technology can provide include:

- Predictive maintenance. This utilizes advanced sensors and machine learning algorithms to detect anomalies and predict maintenance needs before system failures occur, ensuring continuous operation and minimizing downtime.

- Condition-based monitoring. This employs real-time monitoring of crucial parameters such as temperature and pressure, facilitating early detection of potential issues and extending the lifespan of critical components.

- Remote diagnostics. This allows maintenance teams to address issues promptly without being physically present, enhancing safety and efficiency.

Organizations that prioritize sustainability and environmental responsibility are more likely to embrace new technologies and adopt best practices in maintenance. The cultural shift toward sustainability in all-electric CUPs fosters an environment that values innovation, collaboration and continuous improvement.

This shift promotes transparency, accountability and open communication among maintenance teams, enabling them to work cohesively toward common goals. By promoting a culture of sustainability, organizations can drive positive change and create a more resilient and environmentally friendly operation.

The adoption of sustainable maintenance practices in all-electric CUPs aligns with broader sustainability goals and environmental objectives. By reducing reliance on fossil fuels and transitioning to renewable energy sources, these facilities contribute to lower carbon emissions and improved air quality.

The use of eco-friendly materials and maintenance techniques further reduces environmental impact and supports a circular economy model. Sustainable maintenance practices also promote resource efficiency, waste reduction and energy conservation, resulting in cost savings and long-term sustainability.

Key differences. A few areas stand out when summarizing the different maintenance strategies for traditional and all-electric CUPs, which were previously discussed in their individual sections.

First, as noted, traditional maintenance practices tend to be reactive and preventive, focusing on fixing problems after they occur or preventing failures through scheduled maintenance tasks. In contrast, maintenance strategies in all-electric CUPs are proactive and predictive, leveraging advanced technologies and data analytics to anticipate issues before they escalate.

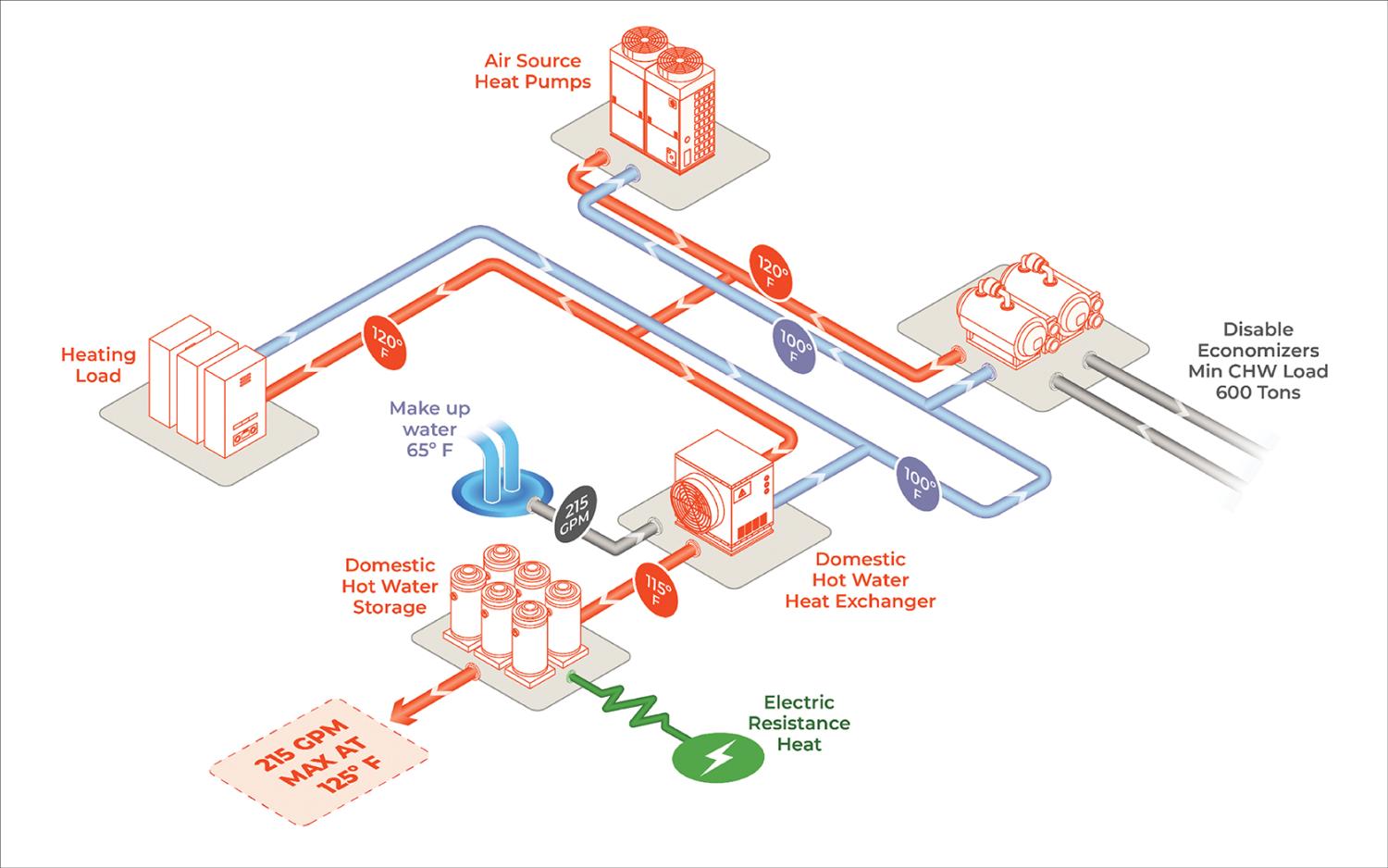

Click image to expand

Likewise, traditional maintenance practices may be entrenched in organizational norms and resistant to change, while all-electric CUPs prioritize innovation and sustainability, fostering a culture of continuous improvement and collaboration. This cultural shift enables organizations to adapt to new technologies and embrace sustainable maintenance practices more readily.

Finally, as discussed, traditional maintenance practices in CUPs powered by fossil fuels present challenges in terms of environmental impact, resource depletion and waste generation. In contrast, all-electric CUPs prioritize sustainability by using renewable energy sources, promoting energy efficiency and reducing carbon emissions.

To assess the effectiveness of maintenance strategies in CUPs, organizations can utilize a range of performance metrics that encompass cultural and sustainability aspects. Some key performance metrics include:

- Energy efficiency. Measure the energy consumption and efficiency of CUPs to identify opportunities for improvement and optimization.

- Sustainability initiatives. Track the implementation of sustainability initiatives, such as renewable energy projects, eco-friendly maintenance practices and waste reduction programs.

- Employee engagement. Assess employee engagement and satisfaction with maintenance practices to gauge the effectiveness of cultural initiatives and teamwork within maintenance teams.

- Carbon footprint. Monitor the carbon footprint of CUPs to evaluate the environmental impact of maintenance activities and energy generation.

- Equipment reliability. Measure the reliability and performance of critical assets in CUPs to identify maintenance needs and optimize asset management strategies.

- Cost savings. Evaluate the cost savings achieved through sustainable maintenance practices, such as reduced energy costs, improved resource efficiency and minimized downtime.

Implementing a comprehensive maintenance strategy that aligns with sustainability goals and cultural values can help CUPs operate more efficiently, reduce environmental impact and enhance overall performance. By tracking these performance metrics, organizations can evaluate the impact of their maintenance strategies on cultural values and sustainability goals, and identify areas for improvement.

Facilities manager’s role

The role of facilities managers in new construction projects is pivotal for the long-term ownership and sustainability of buildings. From the perspective of a construction lead, the collaboration with facilities experts is not only beneficial but also essential for ensuring that new construction meets the long-term operational needs and standards of the organization.

Facilities managers bring a unique perspective to the construction process. Their deep understanding of the day-to-day operations and future needs of the building’s occupants allows them to provide valuable insights that can significantly influence the design and construction phases. This collaboration helps to ensure that the building is not only constructed to meet current needs but is also adaptable to future requirements.

Furthermore, facilities managers help bridge the gap between construction teams and building occupants. Their involvement in the planning and construction phases ensures the needs and concerns of the end-users are considered. This leads to higher satisfaction among occupants and a building that serves its intended purpose.

Some of their key construction and maintenance responsibilities include:

Strategic planning and design. Facilities managers contribute their expertise to create efficient, patient-centric environments, optimizing layouts and specifications to accommodate both current and future technological advancements.

Budget and cost management. Facilities managers play a critical role in managing costs without compromising quality, advocating for cost-effective solutions that maximize the value of investments.

Compliance and safety. Facilities managers ensure the hospital complies with all relevant regulations. This is a primary concern as is the integration of safety and accessibility standards into the hospital design.

The all-electric central utility plant in the foreground of the UCI Health medical complex currently under construction in Irvine, Calif.

Images courtesy of UCI Health

Resilient hospital buildings must have reliable engineering systems appropriate for the clinical and environmental needs of their facilities. Once installed, building systems drive engineering practices and costs for the life of the building.

The role of the facilities manager in project planning is crucial in ensuring that these systems are not only effective but also sustainable and cost-efficient over time. Facilities managers must make the case for life-cycle considerations in system design.

By focusing on the long-term implications of construction choices, facilities managers help to mitigate potential issues that could arise from short-term cost-saving measures. They should advocate for the selection of high-quality materials and systems that are durable and require minimal maintenance.

Similarly, investing in high-quality equipment with long engineered lifespans ensures that the systems will function effectively for an extended period. This reduces the frequency of replacements and repairs, contributing to overall cost savings.

Ease of maintenance also is a critical factor. Systems should be designed and installed in a manner that allows for straightforward and efficient maintenance procedures. This reduces downtime and ensures that hospital operations are not disrupted by lengthy or complicated maintenance processes.

Furthermore, the operating costs of these systems must be kept low. Hospital facilities managers must advocate for designs and systems that are energy-efficient and cost-effective to run. This not only helps in reducing the hospital’s operational costs but also contributes to a more sustainable and environmentally friendly operation.

Lastly, planning for the replacement of major units at the end of their lifespans with minimal to no impact on clinical operations is essential. Facilities managers must ensure that the replacement process is seamless and does not interfere with the critical functions of the hospital.

A significant opportunity

The shift toward all-electric CUPs powered by renewable energy sources represents a significant opportunity to improve sustainability, reduce carbon emissions and enhance operational efficiency. Maintenance strategies play a crucial role in ensuring the reliable and efficient operation of CUPs, with traditional methods being gradually replaced by more proactive and sustainable approaches.

Cultural aspects influence maintenance practices in CUPs, shaping organizational norms, values and communication within maintenance teams. Embracing a culture of sustainability and innovation can foster collaboration, transparency and continuous improvement, driving positive change in maintenance practices.

Sustainability aspects of maintenance practices in CUPs are critical for reducing environmental impact, conserving resources and supporting long-term sustainability goals. By adopting sustainable maintenance practices, organizations can minimize their carbon footprint, improve energy efficiency and contribute to a cleaner and more sustainable future.

Performance metrics such as energy efficiency, sustainability, employee engagement, carbon footprint, equipment reliability and cost savings can help organizations evaluate the effectiveness of their maintenance strategies and identify opportunities for improvement.

By tracking these metrics and aligning maintenance practices with sustainability goals and cultural values, CUPs can enhance their overall performance and contribute to a more environmentally friendly operation.

By embracing innovation, collaboration and sustainability, organizations can optimize their maintenance strategies, reduce environmental impact and improve operational efficiency. And, through a holistic approach that considers cultural and sustainability aspects, CUPs can play a vital role in advancing toward a more sustainable future for generations to come.

Devin J. Hugie, MBA, CHFM, CHC, FASHE, is CEO and a reliability coach with Forum Reliability, Spencer, Ind.; and Joe Brothman, MBA, is director of facilities and general services at UCI Health, Orange, Calif. They can be reached at dhugie@forumreliability.com and jbrothma@hs.uci.edu.