Light on the wallet

It's estimated that hospitals use the most energy on a square-foot basis of any building type and that lighting comprises about 16 percent of the total load. What's more, it's likely to be a higher percentage in older facilities.

It's estimated that hospitals use the most energy on a square-foot basis of any building type and that lighting comprises about 16 percent of the total load. What's more, it's likely to be a higher percentage in older facilities.

It's not unusual for a large health care complex to build portions of its facility decades apart and therefore have different lighting technologies in place for each. For a large health care institution considering an energy retrofit of its lighting systems, a little planning can go a long way toward making the project run smoothly and successfully.

Following the steps

Retrofits can be as simple as a lamp and ballast change-out or they can involve replacing the old lighting system with a completely new one. Determining which job to undertake comes after initial analysis of the age of the system, the lamp and ballast technology in place, the quality of the existing light and the availability of incentive money through energy grants and tax deductions.

In general, the following 10 steps will provide health care facility professionals with the best results:

1. Conduct brainstorming sessions. Prior to beginning work, brainstorming sessions between the hospital stakeholders and a lighting design professional to discuss existing conditions, current technologies and future needs of the facility can begin to establish goals, bring out concerns and construct a reasonable timeline.

2. Establish goals. A summary report of the findings from the brainstorming sessions will establish the goals and expectations of the project and provide a roadmap from which to move forward. This is especially important if the work is to be executed in phases. This should include an executive summary that will highlight the lighting project's scope, complexity and cost.

3. Gather as-built records. Once the project's scope has been established, as-built drawings and specifications should be gathered. In a perfect world, there would be electronic drawings of the facility that call out all of the lighting equipment and it would be 100 percent accurate. However, it's more likely that there are hard copy drawings that have shortcomings and the specifications may not reflect what is actually installed. What to do?

4. Conduct a site survey. The site survey is the next step that will identify what equipment is really in the facility, versus what is thought to be in place. It's preferable to do the site survey electronically if electronic drawing files are available.

To conduct the survey with the utmost efficiency, a laptop and a rolling cart that puts the keyboard at a comfortable working height are required. With this simple set-up, each room's information can be entered and checked efficiently, and discrepancies between the drawings and the actual conditions can be documented. In this manner, the documentation can be prepared completely on-site and does not require rework when the surveyor returns to the office.

San Rafael, Calif.-based Autodesk Inc.'s DWF file format works well for drawing markups because it has tools that make the process quick and easy. In addition to a drawing markup, a spreadsheet with room numbers, brief fixture descriptions and light-level recordings can assist in decision-making later. Both documents can be completed during the survey process.

In most facilities it will be necessary to use a ladder to open fixtures and verify lamps and ballasts. This is not required for every fixture, but a representative sample must be checked. The number of people required to conduct the survey depends on the size of the facility. It can be accomplished by one person, but is most efficient when one person is the identifier of the equipment and another person records everything. This allows the identifier to climb ladders and open fixtures while the other keeps an eye on the spreadsheet and drawing notations.

Light levels vary over time and, if the fixtures recently have been re-lamped, the light levels will be higher than usual. A notation of the relative lamp life should be documented and utilized in the analysis of the project to determine what replacement products should be used. Cleaning the fixtures also can improve the system output, so notations should be taken regarding the overall cleanliness of the fixtures at the time of the survey.

5. Prioritize the improvements. Once the preliminary work is complete, the team can prioritize the work, make recommendations for specific changes and crunch numbers.

To prioritize the work, look first for the low-hanging fruit. These will provide significant energy savings with little cost for materials or labor. They should be followed by the items that require higher cost or more labor, but still have significant energy savings. Finally, items of lesser energy savings and significant labor or cost may be considered.

Low-hanging fruit include situations in which the quality and quantity of light are acceptable and one-for-one lamp and ballast change-outs provide high energy savings. It's critical to know the exact lamp and ballast that are in place so that lumen output and ballast factor can be taken into account when selecting the new equipment. It's also helpful to know when the last re-lamping was done so lumen depreciation can be estimated. When the physical size and shape of the lamp does not change, a comparison of lamp fixture lumens is a valid way of predicting new versus proposed light levels.

If the number or size of the lamp changes, the performance of the fixture will change, so comparing fixture lumens is less accurate. Lamp and ballast change-outs often can be performed by maintenance personnel after normal working hours with little or no disruption to staff.

Where the intensity of illumination is too high or low or the quality of illumination is not right, it may be necessary to change the fixtures. In this case, the first costs will be higher, but satisfaction with the end result also will be higher.

If the quality of the illumination is poor and a facility professional invests in energy savings without fixing the quality issues, it's a waste of money. It's difficult to attribute the quality of illumination directly to the productivity of the worker for most job types. Even so, if improving the quality of the illumination only improved productivity by 0.05 percent, that improvement still would be more valuable than the cost of the improvement because the cost of the staff is usually the employer's highest cost. To change fixture type and quantity, some design work is necessary.

6. Assess the control system. Beyond fixtures, automatic controls also can increase lighting efficiency. Most energy codes now require occupancy sensors or other automatic shut-off devices and daylight controls in certain defined spaces with daylight. Five- to 10-year-old buildings in states with established energy codes may not be able to achieve much additional energy savings from fixtures. However, there may be significant potential in the controls. Daylighting controls may achieve 15 to 50 percent energy savings and occupancy sensors likely will add 15 to 30 percent savings.

The two factors that most influence the effectiveness of daylight controls are the typical hours the room is used and the orientation of the room. North-facing spaces with large daylight openings usually can reduce the electric light levels during most of the daylight hours. South-, east- and west-facing windows also can reduce electric light levels if control of direct sunlight has been addressed with building or landscape elements that eliminate the glare and heat from direct sunlight. If sunlight controls are passive (fixed in place and do not require operator input), photocell control of the electric lighting will be most effective.

The most common active controls are interior window shades or louvers. When they are controlled manually, a user must open and close them as the sun conditions change. Frequently, the user closes them when the direct sun penetrates and simply leaves them in the closed position the rest of the time. When this happens, the daylight controls will turn the electric lights to full output and no energy savings will be realized. It's important to understand whether this condition exists in a facility and to evaluate whether it can be changed.

Automatic controls are not recommended in patient care areas. This is because the need for lighting may vary from what an automatic device would predict. Dimmable light sources are welcomed by patients and caregivers alike as they offer the most flexibility in tuning the light levels. Surveys have found that most people use the lights at less than full output when dimming is available.

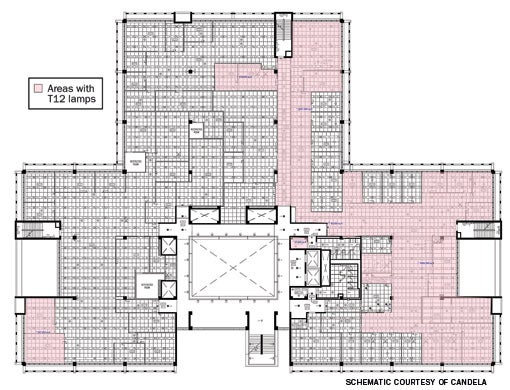

|

| A color-coded drawing that shows where the least-efficient lamps and ballasts are located is a useful tool during the upgrade process. |

7. Prioritize the options. Once the options have been identified and evaluated, they need to be prioritized in a summary document. The spreadsheet from the site survey can be enhanced with the information for the proposed equipment.

8. Identify the funding. If funds already have been allocated, the report also should describe how many of the proposed changes can be achieved within the allocation. If the work is greater than the existing funds will allow, further phases should be described for the remaining work, which could be funded with savings from the first phase.

If some funding is being provided by the local utility, it's important to contact the utility early in the process. It may have limited funds for a particular year, so it could impact the timing of the project. The utility may have unit-price rebates for one-for-one retrofits and another process to identify savings where a more complex renovation is taking place. Utilities usually have specific timeline requirements, so health facility professionals must work within them.

9. Implement the upgrade. Implementation may be achieved by the in-house facilities staff if it is limited to lamp and ballast replacement and wireless controls. However, a licensed electrician is required if the health care facility is adding control devices, changing out fixtures, or doing rewiring. For retrofit projects requiring an electrical contractor, bid documents must be produced that include drawings and specifications. The drawings should identify the existing fixtures and which equipment will be removed, retrofitted and installed. The specifications must include lighting equipment and control equipment.

10. Track the results. Because lighting systems generally are controlled through panels with other electric loads, it's often impossible to see directly the level of savings being achieved.

In some situations, data logging devices can be attached to fixtures in representative spaces and the information can be projected over the whole project. This provides useful information, but is not completely accurate so must be taken with a grain of salt.

There also are some control systems that provide real-time, energy-use data. They are hard to justify for the sole purpose of tracking energy use, but they have many other useful features that may prove valuable for a large facility.

These systems work by providing an individual address to each fixture, which allows the fixture to "talk" to a computer when a lamp or ballast has gone out. This allows the maintenance department to address an outage quickly.

A good investment

Energy-efficient lighting upgrades can save money in energy costs, material costs and labor. When coupled with such other benefits as improved quality and lower maintenance costs, they almost always are a good investment.

Denise Fong, IALD, LEED AP, is principal at Candela Lighting Design and Consulting, a division of Sparling, Seattle. She can be reached at dfong@candela.com.

| Sidebar - Light efficiency and effectiveness mesasurements |

| The following definitions provide assistance in understanding the considerations discussed in the article. For official definitions, refer to the Illuminating Engineering Handbook, which can be purchased from the Illuminating Engineering Society at www.ies.org.

|

| Sidebar - Options to consider when retrofitting |

| A lamp and ballast retrofit seems like a straightforward proposition — the best new systems can be as much as double the efficiency of the systems they are replacing — but there are many options to consider. Ballast factor, input watts and lumens are proportionally related. A low ballast factor equals low energy use (input watts), but also low light output (lumens). When evaluating a possible lamp and ballast combination, all three need to be considered. If existing light levels are satisfactory, but the highest energy savings is achieved with a low ballast factor, the resulting light levels may be too low. This could be counteracted to some degree by starting with a higher output lamp. On the other hand, if the light levels are too high, a low ballast factor could bring the light levels into line without having to change the fixtures or their layout. Finally, lamp life also plays into the equation. Any of the newer options represents a significantly longer life, changing from 20,000 hours to 35,000 hours and some as high as 60,000 hours. |