Plumbing manufacturers meet hospital demands

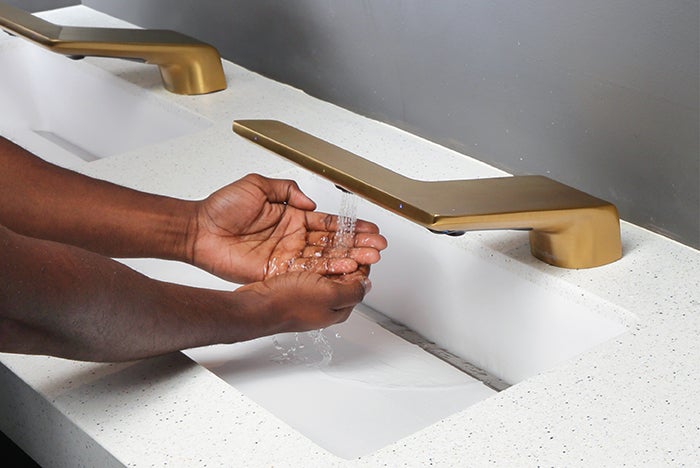

Image courtesy of Bradley Company

The latest plumbing fixtures for hospitals and other health care facilities feature touch-free automation; nonporous and seamless materials; smart technology; cohesive and integrated designs; and construction for minimized splashing.

Infection control is a major focus, with fixture capabilities ranging from automated cleaning and disinfection systems to consumable tracking of soap and hand sanitizer. Additionally, manufacturers continue to advance new ligature-resistant faucets and fittings.

‘A significant shift’

“In the realm of plumbing products for health care, we are witnessing a significant shift toward the integration of smart technology and an emphasis on infection control,” says David Kachurak, director of business development at T&S Brass and Bronze Works Inc., Travelers Rest, S.C. “There’s growing demand for touch-free fixtures, including faucets, soap dispensers and flush valves, to minimize cross-contamination. In addition, there’s a focus on marketing these products as part of a comprehensive infection control strategy, highlighting features such as antimicrobial coatings and easy-to-clean designs.”

One particular challenge to manufacturers serving hospitals is water usage. “While there are instances where lower water usage conflicts with water safety measures, in areas where it makes sense, low-flow outlets and showerheads have become a focus for health care facilities that are trying to maintain costs and save water,” says Greg Hunt, commercial product manager at Chicago Faucets, Des Plaines, Ill.

As hospitals anticipate more water shortages, manufacturers are focusing on improving efficiency. “We’re seeing increased demand for internet-connected smart plumbing components, ranging from water meters and leak sensors to touch-free faucets and low-flow toilets,” says Kristin Kahle, president of Morris Group International’s (MGI’s) Whitehall Manufacturing, City of Industry, Calif. “One example is MGI’s ConTrols BASyC digital mixing valve and monitoring system. This system aggregates real-time data, history and alarms by using sensors to optimize water use and safety.”

BASyC provides around-the-clock monitoring and adjustment for recirculating water, according to Kahle. During a power outage, sensor/actuator failure or other emergency, the system reverts to mechanical regulation, ensuring continued safe water delivery. The safe sanitization override mode helps to minimize Legionella risk.

“We also see more hospitals adopting modular and prefabricated construction methods when it comes to plumbing,” Kahle continues. “These techniques allow for greater quality control, faster timelines and more predictable budgets. The health care sector is adopting prefab and modular solutions to balance efficiency with meeting medical facility needs that require customization.”

Plumbing products manufacturers that supply the nation’s hospitals also are using new materials to improve infection control, durability and sustainability. “In terms of materials, we’re starting to see a trend moving away from stainless steel and laminates toward solid surface and natural quartz,” says Will Haas, senior product manager at Bradley Company, Menomonee Falls, Wis. “This shift may be driven by the preference for a more natural aesthetic, along with greater durability, sustainability and longer product lifecycles.”

Sloan, Franklin Park, Ill., has introduced SloanStone Quartz, which features two molded quartz sink designs. “The sinks have no seams, which makes cleaning easier,” says Morgan Kish, senior product line manager for sinks, faucets, soap dispensers and showerheads. “The molded quartz provides a higher end look and more vandal-resistance than a traditional molded solid surface. The sinks can be used to upgrade the aesthetics of hospital restrooms.”

Willoughby Industries Inc., Indianapolis, designs fixtures that utilize materials other than stainless steel and support therapeutic environments. “Materials such as our AquaSurf solid surface offer a more homelike space, as opposed to an institutional look, and work alongside therapy and medication to help heal patients,” says James Waldrop, director of health care sales.

Hunt at Chicago Faucets says many materials are being used to help reduce the growth of bacteria. “We use copper supply lines for our Patient Care line of HyTronic touch-free faucets, along with antimicrobial outlets. We’re always looking at innovative concepts, both in material and designs, to reduce the areas that are in contact or can retain water, helping hospitals fight the spread of waterborne pathogens.”

Jana Summey, ASSE 12080 Certified–health care market manager at Zurn Elkay Water Solutions, Milwaukee, says safety, sustainability and operational efficiency are driving advances in innovation and technology for plumbing solutions. “Materials that reduce germ transfer and biofilm growth are being used to lower health care-associated infections and their associated costs. In addition, infection prevention and environmental services teams are looking for materials and designs that are easier and quicker to clean and disinfect,” Summey says.

New features

Many plumbing fixtures and fittings recently introduced to the health care facilities market incorporate the above-mentioned features.

For example, Bradley Company has unveiled the all-in-one WashBar, which features touch-free handwashing technology. Its design integrates soap, water and a dryer in a single piece of durable cast metal available in a variety of corrosion-resistant finishes, including chrome. “With LED lighting and icons, the WashBar keeps everything within close reach for an accessible and intuitive handwashing experience,” Haas says. “The dryer and bowl work together to eliminate water dripping onto floors or walls for a cleaner, safer restroom.”

Bradley Company’s matching Verge soap dispenser and faucet sets unify the look of hospital washrooms while delivering dependable, touch-free handwashing, according to Haas. “Optimized sensing eliminates false activations, hidden sensors deter tampering and longer spouts increase handwashing space. The models are available in four styles and six finishes,” Haas says.

T&S Brass and Bronze Works has introduced the ChekPoint faucet series, which includes a ligature-resistant model that is designed to address the challenges of behavioral health facilities. The rounded design reduces the opportunity for self-harm, and the faucet features a flush-mount sensor lens, along with a hidden aerator, to enhance vandal-resistance. It also includes below-deck electronics, safeguarding the components from tampering or damage. “Like all T&S sensor faucets, this model offers a range of adjustable features to meet specific application needs, including auto shut-off, time-out and auto flush settings,” Kachurak says.

T&S Brass and Bronze Works also offers an antimicrobial coating option across a variety of its models, which makes cleaning easy and ensures long-lasting sanitation. The coating acts as a barrier against odor- and stain-causing microbes such as bacteria, mold, mildew and fungi. While it doesn’t eliminate microbes, it creates an environment where they are not able to thrive, according to Kachurak.

Willoughby Industries has been working with some of the nation’s top design firms in behavioral health to manufacture fixtures that have thoughtful design attributes, according to Waldrop. “The fixtures have proven to decrease patient aggression, normalize the physical environment, encourage appropriate behavior and impact the psychology of patients and staff,” Waldrop says. Willoughby Industries also offers an Americans with Disabilities Act-compliant bariatric sink, which provides patients of size with a residential feel while offering facilities a sink that can withstand 1,000 pounds of static, downward force at the front edge in a non-porous, easy-to-clean material.

Among wireless connected plumbing solutions, Sloan offers the SC Argus Pro, which is designed to improve preventive maintenance, health and well-being, and sustainability. Hand hygiene tracking and remote line flushes are two other Sloan offerings for the hospital market. “In addition, Sloan’s programmed water technology is a connected plumbing solution that monitors and controls water usage and minimizes vandalism in behavioral health care facilities,” says Solay Alagappan, senior product line manager.

In the area of improved hygiene, Sloan’s wall-hung clinic service sink features a skirted trap way, which eliminates crevices and seams that can trap germs. It also is available with SloanTec hydrophobic glaze to support the cleaning process.

The Auto-Drain shower systems, available from Chicago Faucets, are designed to work like conventional showers. However, when turned off, the water in the pipes behind the wall, the valve and the shower hose drain automatically.

“This reduces stagnant water in the shower system, which may not be used on a regular basis, helping to reduce the opportunity for the growth of waterborne pathogens,” Hunt says. “The shower hose drains automatically, so hospital staff no longer need to drape or disconnect shower hoses to drain the water.”

Zurn Elkay Water Solutions’ POD Pro floor drain, created for modular patient room applications, is the shallowest floor drain on the market, making installation easy and quick, according to Summey. “The drain is designed for shallow subfloor installations where concrete may not be present and can be adjusted to accommodate 3/8- to 7/8-inch finished floor thicknesses with optional extension shims,” she says. It also can be a sanitary drainage solution because it’s made from Type 304 stainless steel.

Zurn Elkay Water Solutions also has introduced the Hydro-X power flush valve, which delivers improved sustainable performance with renewable, uninterrupted hydropower designed to last the life expectancy of a commercial restroom. “Maintenance demands are fewer because the diaphragm, gaskets and seals last longer than other designs, and its gear-driven technology makes it less susceptible to debris and buildup. The design includes a mechanical override button, allowing the user to flush on demand,” Summey notes.

The new EZ Gear sensor faucets, available from Zurn Elkay Water Solutions, combine ceramic disk operation and sustainable hydropower, and its streamlined waterway enhances auto flushing capabilities. “Connected capabilities allow a hospital to implement automated flushing based on actual water usage to lower the risk of Legionella while supporting sustainability initiatives,” Summey adds.

AcornVac Inc., Chino, Calif., has developed a broad range of toilet fixtures for hospitals. These fixtures include vitreous china models, both on and off the floor. The on-the-floor vitreous china fixture has been well received by health care providers due to its streamlined design, which facilitates cleaning and minimizes areas for debris buildup, according to Laura Marshall, vice president.

“Together with our sister company, Whitehall Manufacturing, we also offer a ligature-resistant, stainless steel vacuum flush toilet with a white Enviroglaze coating, concealed sensor-operated vacuum flush valve and an integral seat for behavioral environments,” Marshall says. “The toilet provides a highly efficient flush using less than half a gallon of water by drawing air into the toilet bowl, which minimizes flush plume and the spread of infectious pathogens from the bowl.”

Durapods, North Wales, Pa., is a manufacturer of prefabricated bathroom pods and building elements that are built in its factories to project specifications. The company handles design, manufacturing and installation of all building elements. Durapods recently completed a health care project featuring 960 bathroom pods as well as an outpatient facility with 98 medical exam rooms and 20 bathroom pods. “Most facilities we deal with are interested in a product that can be built to exact design specifications off-site and delivered to the site ready to install,” says Tony Gardner, director of sales and marketing.

Continued innovation

Manufacturers anticipate continued innovation in the near future, with a focus on integration with building management systems and the Internet of Things. This will enable facilities to control water usage more effectively, leading to cost savings and improved sustainability.

They also expect to see advances in water purification to ensure high standards of water quality. Additionally, there will be ongoing refinement of touch-free technologies and materials to further enhance patient safety.

SMART USAGE

The BASyC digital mixing valve and monitoring system aggregates real-time data, history and alarms by using sensors to optimize water use and safety. Whitehall Manufacturing

DISTANCE LEARNING

The SC Argus Pro enables health care facilities managers to remotely monitor fixtures and water usage without having to enter the restroom. Sloan

SAFETY FIRST

Featuring a rounded design, the ChekPoint ligature-resistant faucet is designed with patient safety in mind. T&S Brass and Bronze Works Inc.

TRIPLE THREAT

The Hydro-X power flush valve reduces germ transfer, assists in sustainability efforts and reduces maintenance for hospitals. Zurn Elkay Water Solutions

KEEPING IT CLEAN

The Auto-Drain shower system reduces stagnant water in the shower system by automatically draining the valve, pipes and hand spray hose. Chicago Faucets

ACCESSIBLE EFFICIENCY

The vitreous china vacuum toilet is American with Disabilities Act-height-compliant, includes a wall waste connection and is designed to provide an efficient flush using less than half a gallon of water. AcornVac Inc.

STRENGTH AND BEAUTY

This bariatric sink offers patients of size a residential feel while providing facilities with a sink that can withstand 1,000 pounds of downward force at the front edge. Willoughby Industries Inc.

Neal Lorenzi is a Mundelein, Ill.-based contributor to Health Facilities Management.