Emergency power monitoring generates efficiency

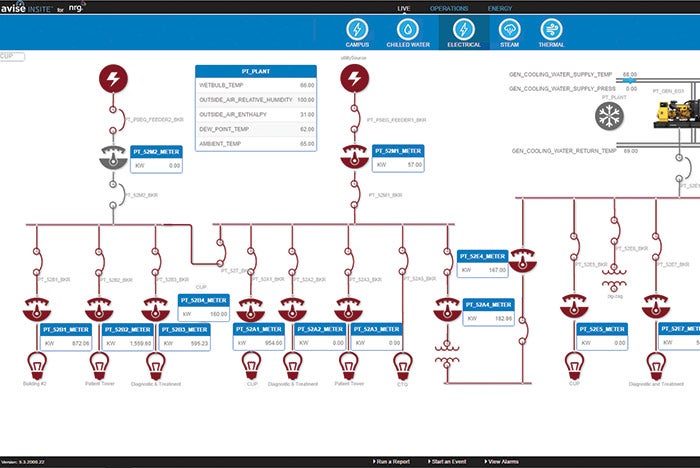

Real-time status and data of an electrical single line diagram provided by Blue Pillar’s Aurora platform.

As a state-of-the-art medical center, driving best practices in facility compliance is a strategic initiative for Houston Methodist Hospital. With its large campus that includes many buildings and pieces of equipment, compliance of emergency power supply systems (EPSS) can be complicated.

Testing, reporting and record-keeping can be extremely difficult to coordinate when generators and automatic transfer switches are on the top floor of one building and in the basement of other buildings across the campus.

Before automating the process, a team of five to six facility professionals armed with clipboards and stopwatches walked across acres of property to get from one generator to the next, taking readings and writing reports.

When John Cook, director of facility management services, joined Houston Methodist Hospital at Texas Medical Center, he quickly set out to make the EPSS compliance process more efficient and accurate by implementing an automated testing system.

“At Houston Methodist, compliance and patient safety are our top priority, and we are early adopters of industry-leading technology,” Cook says.

The Joint Commission and DNV accreditation organizations require testing and maintenance of emergency power and backup systems. Joint Commission Standard EC.02.05.07 was one of the most frequently cited for noncompliance in 2013, with 23 percent of surveyed hospitals named.

Houston Methodist explored improving the compliance process first by using its building automation systems. As at many hospitals, the equipment that comprised Houston Methodist’s EPSS was installed at different times and was made by several different manufacturers.

Facility staff struggled to connect the diverse set of EPSS equipment without customized supervisory control and data acquisition (SCADA). The system typically provides remote monitoring, control and data collection through the use of multiple software and hardware elements, and must interact with and control machines and devices.

Instead, Cook turned to Blue Pillar, Indianapolis, which offered a newer software solution that could connect to any EPSS asset regardless of make, model, vintage or protocol and without requiring customized SCADA development.

After conducting a short site survey, Blue Pillar’s self-configurable Aurora gateway software and retrofit kits were installed. The hospital connected eight generators, 66 automatic transfer switches and 15 meters into a systemwide, secure network without the need for customized development.

Once installed, Blue Pillar’s system began gathering data from all assets. This allowed real-time visibility and control, and provided remote testing and monitoring capabilities.

With the technology in place, Houston Methodist has fully automated the compliance reporting of its EPSS through a centralized, digitally enabled platform that allows facility staff to review testing results anytime, anywhere with mobile devices.

The solution reduces the time and effort required to prepare for an accreditation audit by about 1.5 hours per EPSS test. Multiple systems can be tested at the same time and the reporting process is streamlined, consistent and accurate.

As an added benefit, potential equipment failure or performance issues of the backup system are identified in time to address them, ensuring a higher level of patient health and safety. The system has worked so well that Houston Methodist is ready to expand its use in several buildings on the campus.

“We purchased Blue Pillar for compliance reasons, and now find ourselves logging on to the system for data collection and built-in reports, such as load studies,” Cook says.

“The medical campus is evolving at light speed. We are looking to expand our use of the system and it has no problem keeping up,” he says.