Sustainable materials prove to be prudent investment

|

| Click here for a slideshow |

Health care organizations can gain a number of returns by investing in sustainable interiors. Green interior design enables facilities to be responsible stewards of environmental health and safety as well as the financial health of an institution; it also correlates the mission of a facility with its materials.

“The conversation has gone from sustainability … to the notion of materials being healthful,” says Blake Jackson, AIA, LEED AP BD+C, WELL AP, associate and sustainability practice leader, Tsoi/Kobus & Associates, Cambridge, Mass.

Sustainable options

Healthful materials generally can be obtained at little or no additional cost — and sometimes can cost even less.

“For hospitals, the focus on indoor-air quality for occupants’ health is where there’s a lot of low-hanging fruit in sustainable materials, both from contributing to overall sustainability and from an ROI perspective,” says Robin Guenther, FAIA, LEED Fellow, sustainable health care design leader in the New York City office of Perkins+Will and senior adviser to environmental health care group Health Care Without Harm. In the past, facilities often paid a premium for materials that did not emit volatile organic compounds. “But, by and large, those materials have become much more cost neutral as they’ve become the predominant materials in the marketplace,” Guenther says. This is a huge benefit to health care, she adds, given that much painting and refinishing work in hospitals occur while people are in occupancy.

You may also like |

| 2015 Sustainable Operations Survey results |

| Hospitals size up the value proposition of going green |

| Interview with Kaiser’s Kathy Gerwig on greening health care |

|

|

According to Guenther, materials with recycled content also have been integrated into the market to the point that they no longer come at a premium. This is becoming true for interior products in general. “Manufacturing is moving toward being more proactive about these things, so we’re not seeing an additional cost,” Jackson says. Manufacturers are looking to remain relevant to a market concerned with material health; in addition, they’re realizing benefits from not having to buy and handle as many regulated chemicals. As a result, “we notice that we have way more options for healthful materials than we did in the past,” Jackson says.

Guenther says newer product entries, which are produced at a smaller scale, sometimes come at a higher initial price that tends to equalize with the price of non-sustainable options as production ramps up. “If health care wants better materials and healthful materials, more sustainable materials, they have to be willing in a way to invest in growing those markets,” she says. In addition, health care organizations can use their buying power to actively influence manufacturers to develop sustainable alternatives. “At 18 percent of the GDP, if health care can consolidate and ask for a healthful product, the market is going to deliver,” she says.

Healthier Hospitals Initiative

Monica L. Nakielski, program manager, sustainable initiatives, for Partners HealthCare, Boston, says this was part of the reason for the creation of the Healthier Hospitals Initiative (HHI), a program working to develop a more sustainable business model for the health care sector. Partners was a founding member of the HHI along with several other leading health care organizations, including Dignity Health, Advocate Health Care and Kaiser Permanente. “Our hope in joining efforts is to demonstrate aggregate demand and commitment, consequently accelerating these products coming to market and reducing the price,” she says.

In January 2015, the Massachusetts fire code was changed to no longer require facilities with automatic sprinkler systems to utilize fire-retardant chemicals in furnishings. Nakielski compiled six months of purchasing data to determine how much Partners was paying to have these chemicals added to seating products. This was part of an overall effort to reduce chemicals of concern at the organization’s facilities. She learned that there was an approximately 30 percent upcharge for added fire retardants. She also learned that manufacturers were open to working with Partners to provide the system with more suitable products that did not contain fire retardants or other chemicals of concern.

“Having these conversations with the manufacturers and letting them know that we no longer wanted these chemicals in our products was well-received,” she says. “They themselves had their own teams focused on climate, health and wellness, and they wanted to eliminate these chemicals as well.”

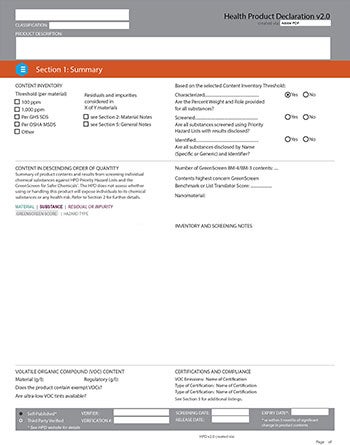

With the new emphasis on healthful materials, manufacturers have become more aware of and transparent about sustainability issues in their supply chain and manufacturing processes. Many manufacturers are issuing Health Product Declarations or Environmental Product Declarations, which outline a product’s material contents and its potential health hazards and environmental impact from the point of extraction to the point of sale. “It’s been a huge marketing advantage for the manufacturers,” says Jackson. “They’ve actually been able to reduce costs and give healthful products to their consumers.”

Hackensack (N.J.) University Medical Center is in the midst of campuswide lobby upgrades designed to meet the Healthy Interiors goal of the HHI’s Safer Chemicals Challenge. This challenge identifies a number of chemicals to be avoided in interior products because of health concerns. Kyle Tafuri, senior sustainability adviser, Hackensack UMC, says the medical center is realizing the 30 percent savings on flame retardant-free furnishings for this project. In addition, they’ve been working with their group purchasing organization on ways to drive the cost down for other products that can help the hospital to meet the Healthy Interiors goal.

“That being said, we really do this because it’s in line with our mission,” Tafuri adds. “Just because something doesn’t give us an immediate cost savings from purchasing, it doesn’t mean we’re not going to invest in it.”

Healthy impact

Tafuri acknowledges that in today’s health care market, providers can be reluctant to make investments without being assured of payback. For this reason, Hackensack UMC is working to obtain concrete numbers to illustrate the overall ROI of sustainable design. Areas under analysis include the health of people who work in the medical center’s facilities. This is especially important to the organization’s finances because most of the workers have health insurance through the medical center, he explains.

Nakielski says that through anecdotal research and conversations with staff members at Boston’s Spaulding Rehabilitation Hospital, a LEED Gold-certified facility that Partners opened in 2013, the health system has learned that some people who were experiencing problems like asthma and headaches in the previous facility felt better as soon as they started working in the new building. In a study published last October in Environmental Health Perspectives, a publication of the National Institute of Environmental Health Sciences, researchers from the Harvard T.H. Chan School of Public Health, the State University of New York Upstate Medical School and Syracuse University demonstrated that people who work in sustainably designed office environments perform better on tests of higher-order cognitive function than people in conventional office spaces. “We all intuitively sensed that it’s a good thing to get rid of these chemicals, but now we have evidence-based research telling us it is, in fact, the case, and supporting many of those business decisions,” says Nakielski.

|

| Health Product Declaration forms allow a manufacturer to provide transparency regarding their product’s material contents, and potential health hazards and environmental impact from the point of extraction to the point of sale. | Image courtesy of Health Product Declaration Collaborative |

“Health care is unique in the world of commerce, because it does have this health mission,” says Guenther. The health of patients, family members and staff in a facility, as well as that of people in the broader community, is the central concern of health care providers. This is reflected in the design of the University of Minnesota Masonic Children’s Hospital, Minneapolis. The building’s interior design, which itself features sustainable materials, has a theme celebrating the importance of cultural diversity and healthful environments around the world.

“All of health care reform preaches prevention,” says Tafuri. “We’re looking at true community health. And safer chemicals, in my mind, are No. 1 in that realm.”

Maintenance and energy benefits

Health facilities can protect an investment in sustainable interiors by choosing the correct applications and maintenance protocols for these materials and finishes. Working with user groups from early in the design process through commissioning is the best way to ensure choosing interior applications that are durable and that can be maintained as needed, while also supporting the goals of sustainability, Jackson says.

With less equipment and fewer chemicals required, ease of maintenance can be a major benefit of more healthful materials. A simple, durable, easily maintained facility was one of the main goals in the design of Boston Medical Center’s Carl J. and Ruth Shapiro Ambulatory Care Center, Jackson notes. “When you have that as a design mode, it’s easier to work in healthful materials options because they’re easier to clean,” he says. The Shapiro Center was a pilot project for the Green Guide for Health Care v2.2, a guide developed by Health Care Without Harm and the Center for Maximum Potential Building Systems Inc. for creating high-performance healing environments.

Interior products can have sustainability benefits besides material health. Energy usage, for example, can be affected by lighting and other interior design choices. Utility providers are incentivizing facilities to use less energy, which can result in substantial financial benefits for facility owners. Jackson notes a recent laboratory design project for which the local utility company paid 75 percent of the cost of a drop ceiling, due to the reduced energy demands of this design element. The owner received a $1.25 million check from the utility provider the first month of operation, a payment based on the building’s mechanical equipment and interior finishes, he says.

Patient satisfaction

For a master’s thesis submitted to Texas A&M University in 2012, researcher Eren Ulusoy compared LEED-certified hospitals with non-LEED-certified hospitals in terms of financial indicators and patient satisfaction.

The study showed that non-LEED hospitals were performing better in regard to the cost of plant operations and profitability, but patient satisfaction and inpatient revenues were significantly higher at LEED-certified hospitals.

“The same people who are investing in LEED-certified buildings are investing in a culture of health and well-being in their buildings and their operations. That is what makes the organization stand out,” says Guenther. “Healthful materials are intrinsic to that message.”

For more information

The following organizations and resources were mentioned in the article:

• Center for Maximum Potential Building Systems: http://www.cmpbs.org/

• Green Guide for Healthcare: http://www.gghc.org/

• Health Care Without Harm: https://noharm.org/

• Healthier Hospitals Inititiative: http://healthierhospitals.org/

• U.S. Green Building Council’s LEED program: http://www.usgbc.org/LEED/

• EPD International: http://www.environdec.com/

• Health Product Declaration Collaborative: http://www.hpd-collaborative.org/