Advances in floor cleaning equipment

Low noise levels, ergonomics, maneuverability and ease of use are some of the variables that health care facilities managers need to consider when selecting floor cleaning equipment. They also should seek out equipment that can handle a variety of hospital flooring challenges as well as water conservation features that provide hygienic results.

These features are available on the latest floor cleaning equipment, according to manufacturers that supply the nation’s hospitals. Equipment that is compact, maneuverable and has noise-dampening components increasingly is being used to clean patient rooms and other health care spaces. In addition, ecofriendly options are available that eliminate the need to use multiple chemicals, which ultimately reduces supply chain costs.

Raising productivity, reducing costs

Experts note that the latest floor cleaning machines focus on increasing productivity and reducing cleaning costs, addressing the issue of the high cost of maintenance and budget cuts with which hospitals must contend. Many say that patient experience also plays a role in new floor cleaning technology.

You may also like |

| Floor cleaning and maintenance basics |

| Efficient hard floor maintenance |

| Manufacturers make hard flooring safer |

| |

Recent additions to the market include solutions for hard-to-clean and high-traffic areas. In addition, machines are being built for quieter operation. Also, respiratory problems and other health issues associated with air contaminants create a need for floor cleaning equipment and practices that do not diminish indoor air quality, while improved water purification helps to eliminate bacteria.

“New technology is available that can reduce the use of conventional cleaning chemicals, reducing exposure to volatile organic compounds and fragrances for patients who may have chemical sensitivities,” says Rick Cohn, health care manager, Tennant Co., Minneapolis. “High-efficiency, particulate air filters on vacuums improve indoor air quality by reducing the level of airborne particles, including those associated with allergens.”

Also, advances in rapid-drying, carpet cleaning technology enable more frequent interim carpet cleaning with minimal disruption. These quieter machines dry carpet in 30 minutes or less and allow cleaning to be performed while patients and visitors are present, Cohn adds.

Historically, hard-floor care equipment has revolved around traditional disc floor machines and scrubbers. Although disc or rotary units are still in wide use, cleaning equipment manufacturers have responded to new types of flooring by offering both cylindrical and orbital technology.

“Each of these technologies helps to tackle the different floor care challenges seen today,” says Michael Schaffer, senior executive with Tacony Corp., commercial floor care division, St. Louis. “There have been significant advances in noise reduction as well, making the use of automated cleaning equipment more practical in noise-sensitive environments.”

Recent introductions

Among a wide range of equipment available to the health care market, Nilfisk, Plymouth, Minn., offers orbital scrubbers in walk-behind, stand-on and rider models, as well as a floor machine. These orbital scrubbers use a detergent dispensing system that allows the operator to use the minimal amount of detergent needed for cleaning an area, while providing a burst of power in heavily soiled areas.

The stand-on and rider models feature a quiet mode that permits daytime cleaning in sound-sensitive areas. Also, the minimal water used with the orbital scrubbers can reduce a facility’s water consumption. Paired with a squeegee design, they leave floors dry in a single pass, says Kim Waldvogel, national account manager, health care, Nilfisk.

One challenge that hospitals pose is the increased use of ultra-hard or epoxy-type floor finishes, which can make it difficult for traditional orbital scrubbers to remove this finish using plain water. “Using these types of finishes forces facilities managers to resort to conventional floor stripping, forgoing the cost and labor savings that chemical-free finish removal affords while increasing floor maintenance complexity," says Waldvogel.

New orbital floor machines, however, have overcome this challenge because they have the power and weight to cut through these types of finishes, Waldvogel notes. Orbital scrubbing technology allows the operator to remove floor finish using water only, nearly eliminating the need for conventional stripping methods.

Tennant Co. recently introduced the T300 Walk-Behind Scrubber, which allows operators to choose from multiple machine configurations to optimize cleaning performance across a variety of hard surface conditions found in hospitals. Configuration options include single-disk, orbital, dual-disk and dual-cylindrical. The T300 can be used with ec-H2O NanoClean, a detergent-free technology that helps hospitals reduce the environmental impact of cleaning.

“Not only are soils removed, but no chemical residue is left behind, so hospital floors retain that polished look with simplified ongoing floor maintenance,” Cohn explains. “Scrubbers using ec-H2O NanoClean can scrub three times longer with a single tank of water and use 70 percent less water than conventional floor scrubbing methods. This allows hospitals to replace many of the chemical solutions they may be using in their current scrubbers.”

Betco Corp., Toledo, Ohio, has introduced a line of automatic Stealth scrubbers, so named because they operate at 54 dBA (comparable to the sound of a dishwasher running in the next room). This allows floor cleaning any time of the day without fear of disturbing patients or staff. The company’s new floor cleaners also feature Malodor Sensory Technology, which destroys any health care-related odor that the cleaner encounters.

“Malodor technology achieves complete transformation of the odor-causing molecule, thus eliminating the odor, not just covering it up,” explains Scott Blakely, vice president, marketing. “The technology first attaches to odor-causing molecules and then permanently transforms the molecules while precipitating to the ground.”

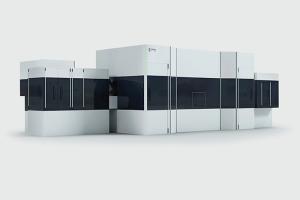

The new TASKI swingo 2100 micro scrubber drier from Diversey Care, a division of Sealed Air Corp., Zurich, Switzerland, is an ultracompact rider machine that covers large areas, up to 5,000 square meters, and works autonomously for long periods between refills and recharges, the company states.

The machine includes an offset feature designed to clean up against walls and the floor edge in a single pass. It also uses low-energy LED lighting, which allows operation for longer periods of time without drawing excessive battery charge. This is ideal for low-ambient lighting applications and promotes machine visibility to improve safety. An “active sitting” driving position reduces operator fatigue while allowing easy access to cleaning areas, the company states. Also, machine speed is automatically reduced when turning to promote stability.

Advances in automation

Intellibot, recently acquired by Sealed Air Corp., offers a line of robotic, hands-free floor cleaning machines for the health care industry, according to Stephen Dalton, Intellibot integration leader. The line includes:

• Hands-free cleaning systems. These allow the operator to push a button and walk away while the machine cleans.

• Eco Save. A four-stage recycling system that can filter water down to one micron, providing clean, reusable water. These machines reduce, reuse and recycle water to eliminate 85 percent of water and chemicals used during each shift.

• Intelli-Trak telemetry system. This addresses the issue of remote diagnostics and repair, and provides for fleet management of floor cleaning activity, which translates to reduced downtime and faster response to service issues. The cleaning crew can multitask because the robots clean the floors while the custodians clean hot spots or high-touch areas.

Dalton sees robotic cleaning as the next evolution in floor care. “While still in its infancy, the demand for automated cleaning machines is growing rapidly, particularly in developed markets, due to significant advances in technology, labor shortages, and the need for higher productivity and training in daily cleaning tasks,” he explains. “Floor cleaning robots will address the issues of rising labor costs, scarcity of labor, and increased demand for electronic tracking and data records. The robots will deliver a new level of performance that will increase productivity throughout health care.”

Handling small jobs

New floor cleaning equipment is being designed for use in smaller, off-site facilities, a growing trend in the health care marketplace. Small, battery-operated microscrubbers can be transported between facilities; they are quiet and can clean around and under obstacles. Small, self-contained carpet extractors also are available for these facilities.

Rex Shull, product manager at Kärcher North America, Englewood, Colo., says a number of new machines are available to clean these smaller facilities. One is the Kärcher BR 35/12 scrubber, a maneuverable microscrubber with a four-gallon tank. It runs at low 62 dBA noise levels. “The lithium-ion battery pack allows for extended run times and charge times of less than one hour,” Shull says. “The steerable head rotates 200 degrees, allowing operators to get under desks, around furniture and into corners. Due to its compact size, the unit can be stored in a closet.”

Kaivac Inc., Hamilton, Ohio, developer of No-Touch Cleaning and OmniFlex Crossover floor cleaning systems, recently introduced an OmniFlex AutoVac with lithium-ion smart battery technology. The cordless system can clean up to 20,000 sq. ft. per hour. Also, there is no need for workers to dust mop floors before using the machine.

Sitting atop a self-dispensing trolley bucket, fresh cleaning solution is applied directly to the floor to be cleaned. As it is dispensed and the machine moves over the floor, the system simultaneously spreads the cleaning solution and provides enough agitation to loosen soils — all of which are suctioned by the AutoVac.

Tacony Corp. has introduced a line of small automatic floor scrubbers, which apply cleaning solution onto the floor, scrub it and then vacuum the floor dry in a single pass. “In the past, these machines have been quite large and were restricted to use in hallways and other open areas,” Schaffer says. “Our small floor scrubbers can be used in patient rooms, nurse stations and other tight areas that could only be mopped by hand in the past.”

Sustainable and safe

In the future, floor cleaning equipment in health care environments will become even more sustainable and safer to use, says Cohn of Tennant Co. Machines are being designed for easier clean-out, quieter operation, and with better filtration on vacuums and burnishers, he says.

Among equipment manufacturers, the focus has changed from cleaning for appearance only, to cleaning for health and safety too, says Schaffer of Tacony Corp. “We will continue to see cleaning equipment and related technologies that support the needs of urgent care and outpatient centers as different types of medical services move beyond traditional settings.”

Neal Lorenzi is a freelance health care writer based in Mundelein, Ill.

| Ready to workThe BR 18/11 automatic scrubber meets rigorous global user standards for durability. |

| Quick maneuversThe battery-operated BR35/12 microscrubber with steering capability allows operators to turn in and out of tight areas. |

| Anywhere, anytimeThe SC500 is an orbital scrubber, ideal for daytime cleaning in hallways and patient rooms. |

| Look, no handsHydroBot is a hands-free scrubber for hard surfaces and suitable for health care environments. |

| Sound efficiencyThe Stealth MicroRider lowers cleaning costs by 36 percent and operates at 54 dBA. |

| Covering groundKaivac’s battery-powered AutoVac System can clean up to 20,000 sq. ft. per hour. |

| Compact convenienceTASKI Swingo is a micro ride-on scrubber that combines compact design with high performance and high flexibility. |

| Leave no traceThe T300 Walk-Behind Scrubber can be used with ec-H2O NanoClean, a detergent-free technology that helps hospitals reduce the environmental impact of cleaning. |