Advanced degree

Project Overview

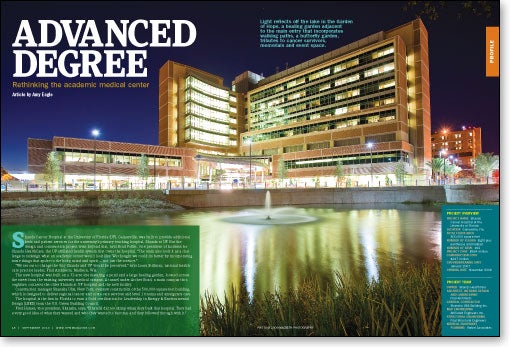

Project Name Shands Cancer Hospital at the University of Florida

Location Gainesville, Fla.

Total floor area 500,000 square feet

Number of floors Eight plus penthouse and helipad

Number of beds 192

Project cost $364 million

Construction cost $217 million

Groundbreaking date January 2007

Opening date November 2009

Project Team

Owner Shands HealthCare

Architect, Interior Design and Landscaping Flad Architects

General Contractor Skanska USA Building Inc.

MEP Engineering Affiliated Engineers Inc.

Structural Engineering Flad Structural Engineers

Medical Equipment Planning Korbel Associates

Shands Cancer Hospital at the University of Florida (UF), Gainesville, was built to provide additional beds and patient services for the university's primary teaching hospital, Shands at UF. But the design and construction project went beyond that, says Brad Pollitt, vice president of facilities for Shands HealthCare, the UF-affiliated health system that owns the hospital. "The team also took it as a challenge to redesign what an academic center would look like. We thought we could do better by incorporating some things that spoke to the body, mind and spirit — not just the science."

"We set out to change the way Shands and UF would be perceived," says Laura Stillman, national healthcare practice leader, Flad Architects, Madison, Wis.

The new hospital was built on a 32-acre site featuring a pond and a large healing garden, located across the street from the existing university medical campus. A tunnel under Archer Road, a main campus thoroughfare, connects the older Shands at UF hospital and the new facility.

Construction manager Skanska USA, New York, oversaw construction of the 500,000-square-foot building, which is designed to deliver regional cancer and acute-care services and level 1 trauma and emergency care.

The hospital is the first in Florida to earn a Gold certification for Leadership in Energy & Environmental Design (LEED) from the U.S. Green Building Council.

Fred Hames, vice president, Skanska, says, "[Shands] did not skimp when they built that hospital. They had a very good idea of what they wanted and who they wanted to become, and they followed through with it."

Historic yet modern

The building is constructed of architectural precast concrete with inlaid brick. The red brick matches that of older campus structures; the precast resembles the limestone used in many of these buildings as well. Curved glass and expanses of curtainwall give the historic materials a more modern, welcoming appearance to help mitigate the stress of coming to the hospital, says Jeff Raasch, AIA, LEED AP, design principal, Flad.

Glass walls fill the lobby with natural light, the quality of which changes throughout the day to create a variety of experiences.

More curves are found in the lobby's terrazzo flooring design, which was inspired by swirling images of subatomic particle collisions and the circular forms of cyclotron particle accelerators, in reference to the role of molecular and subatomic research in finding cures for cancer.

The lobby features two interactive multimedia donor recognition pieces by Portland, Ore., firm Downstream. These include touchscreens that display artwork and play videos honoring Shands donors, patients and employees. The videos serve to introduce and underscore the hospital's core vision, which it calls the "Science of Hope."

Natural wood and stone help create a soothing, non-institutional environment connected to the outside world. This is enhanced by views of the garden from every floor, wall-to-wall windows in the patient rooms and windows at each end of every corridor. Cherry-toned wood veneer takes its hue from the hospital's brick exterior. The neutral interior color palette includes a soft green chosen to complement the outdoor views.

In the patient rooms, wood-look vinyl flooring and fiber-reinforced laminate wainscot give the appearance of natural materials in a more cleanable form. "We were thoughtful about trying to use some products creatively and get the aesthetic we were looking for without losing the hospital's ability to maintain it and keep it sanitary and healthy," says Alana Schrader, IIDA, LEED AP, NCIDQ, interior designer and senior associate, Flad.

To facilitate patient care, the rooms include 4-foot-wide doors and patient lifts. Every patient bathroom meets the accessibility requirements of the Americans with Disabilities Act.

Innovative details

The project team worked to improve the entire hospital environment for patients, visitors and staff.

The main circulation stair is designed to encourage people to walk between floors rather than use the elevators, in keeping with the hospital's values of energy conservation and wellness. The hospital's north stair is wrapped in glass on three sides, with views of natural areas, the UF campus and stadium and, of special interest to visiting children, the hospital's helipad.

To reduce walking distances, the stairway was built at the midpoint of the floorplate. Pollitt says this design has been well-received by visitors and staff, who are using the stairs more than ever.

In the surgical department, 10-foot-6-inch-wide corridors allow space for mobile equipment to be stored along the hallway in designated areas marked by the flooring pattern. According to Shannon Liggett, AIA, project architect, Flad, this new concept worked very successfully and was even encouraged by the Florida Agency for Health Care Administration.

Lighting choices were carefully considered throughout the building to ensure caregivers have appropriate task lighting but patients are protected from the glare of overhead lights.

Patients are given control over their environment where possible. In the infusion areas, for example, adjustable privacy curtains allow patients to visit with others, enjoy outdoor views or block out sunlight, as they prefer.

Family in mind

Visitor amenities include overnight accommodations in the patient rooms, respite areas on each patient unit, a cancer resource center, a dining terrace overlooking the garden, a nondenominational chapel and a meditation room. "A patient comes with a family. We need to be able to treat the family as well," Pollitt says.

He recalls seeing a father and daughter reading a book together in comfortable chairs in a spot overlooking the hospital pond on the day the new building opened.

"I can't give them their living room, but I can give them something close to it," he says.

Amy Eagle is a Homewood, Ill.-based freelance writer and a regular contributor to Health Facilities Management.

| Sidebar - Project collaboration is key |

| Shands Cancer Hospital was designed and built using an integrated project delivery (IPD) method that involved the owner, Shands HealthCare; architecture firm, Flad Architects; and construction management firm, Skanska USA; as well as major subcontractors, from the project's beginning. "We generally like a collaborative group," Brad Pollitt, vice president of facilities, Shands HealthCare, says of the teaching hospital. "Part of that is academia. Our general approach is, more minds working on the process are probably better." With its emphasis on collaboration and communication, IPD is generally recognized as a way to control costs, improve quality and increase efficiency in design and construction. This held true for Shands Cancer Hospital, a 500,000-square-foot, LEED-Gold certified facility that was built in just 48 months with no value engineering required to meet the project budget. IPD also influenced the hospital's overall design. One of the building's most notable features is its great amount of curtainwall glass. The glass provides natural light to the facility and gives it a contemporary look that sets it apart from other structures on the University of Florida, Gainesville, campus, despite the use of similar exterior materials. According to Jeff Raasch, AIA, LEED AP, design principal, Flad, the original design had punched windows. In working with precast concrete manufacturers, curtainwall manufacturers and mechanical, electrical and plumbing engineers early in the schematic design phase of the project, the architects learned it would be more cost-effective and easier to erect the curtainwall. Without this early cooperative effort, "the building would have looked completely different," he says. Raasch adds that talking with precast and curtainwall manufacturers about component shapes and installation also helped clarify how the building would go together, which facilitated construction document development and shop fabrication. |

| Sidebar - Partnering for better utility service |

| Rather than run its own central utility plant, as is customary for hospitals, Shands Cancer Hospital formed a unique partnership with its local utility company to operate a plant on-site at the hospital's new facility. While designing the building, "we decided early on that producing energy is not a core hospital function," says Brad Pollitt, vice president of facilities, Shands HealthCare. The partnership is the result of lengthy negotiations between the hospital and Gainesville Regional Utilities (GRU). "We spent several months getting to know each other and getting to understand how the finances work on both sides so we could come up with an equitable agreement," Pollitt explains. The utility operates a 4.5-megawatt gas-fired turbine generator in the GRU Energy Center, which is located on the hospital campus. This plant powers the entire hospital—not just emergency outlets—even if the entire area's electrical grid goes out. The heat from the generator is converted to steam to run two-thirds of the hospital's air-conditioning load, plus hot water re-heat, steam for sterilization and domestic hot water. This is heat that would otherwise simply go up a smokestack if it were produced at a traditional offsite power plant. The system earned the hospital innovation credits toward Leadership in Energy & Environmental Design (LEED) Gold designation from the U.S. Green Building Council. The energy plant is serviced by large, stable, high-pressure industrial gas lines. But in the event of a catastrophic generator failure, the hospital also has two primary feeds from the local utility that come through hardened lines, plus the essential emergency power system required by hospital building codes. Although a full year's operation will be necessary to evaluate costs accurately, expenses were on track with projections in the hospital's first six months. During this time, the Gainesville area electrical grid experienced three brownouts, but "we [didn't] even see a blip at the hospital," says Pollitt. |

| Sidebar - SPEC SHEET |

| Principal Design Materials Access floors: Tate Access Floors Inc. Carpet tile: InterfaceFlor and Mohawk Industries Inc. Carpet: Tandus Flooring Ceiling: Armstrong World Industries, Rulon Company and USG Corp. Colored concrete: The Bomanite Corp. and L.M. Scofield Co. Cubicle curtains: Arc-Com Fabrics Inc. and Maharam Curtainwall framing: T.S.G. Industries Inc. |